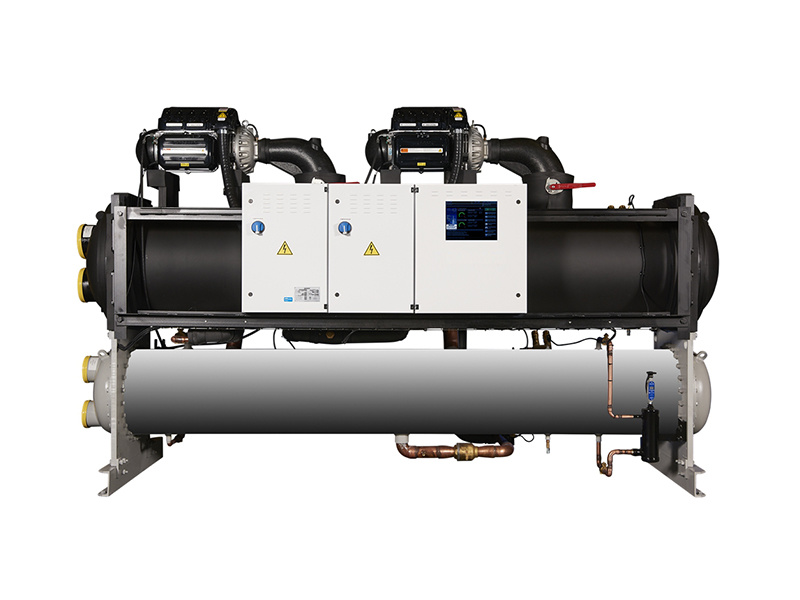

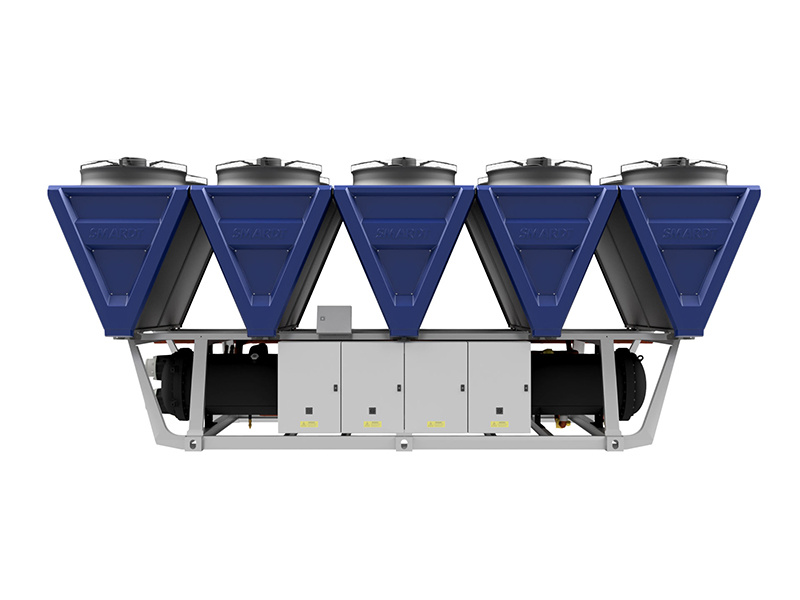

Evaporative air-cooled chiller

Evaporative-cooled screw chillers utilize evaporative condensers, which combine the advantages of water-cooled and air-cooled systems. A water film forms on the condenser surface, absorbing heat from the refrigerant through evaporation. Simultaneously, airflow carries away the water vapor produced by the evaporating film, resulting in highly efficient heat exchange. Compared to traditional water-cooled condensers, evaporative cooling offers higher heat transfer efficiency, providing greater cooling capacity at the same energy consumption. Compared to air-cooled condensers, it offers more stable cooling performance in high-temperature environments and relatively lower energy consumption.

- Cooling capacity range: 90KW to 3200KW

- Temperature control range: 5℃ to 30℃

- Temperature control accuracy: ±1℃

- Refrigerant: R22, R407C, R134a

- Installation environment: Outdoor installation

- Non-standard customization: Explosion-proof type, corrosion-resistant type

- Optional: MODBUS RTU protocol RS485 remote communication, energy-saving frequency conversion

Category:

Medium temperature series

Product Attachment:

Evaporative cooling chiller units have the following characteristics and advantages:

1. High efficiency and energy saving:

- High-efficiency heat exchange: Evaporative cooling screw chillers use evaporative condensers, which combine the advantages of water cooling and air cooling. Water forms a film on the surface of the condenser, absorbing heat from the refrigerant through the evaporation of the water film. At the same time, air flowing through the condenser carries away the water vapor generated by the evaporation of the water film, thus achieving efficient heat exchange. Compared with traditional water-cooled condensers, evaporative cooling has higher heat exchange efficiency, providing more cooling capacity with the same energy consumption; compared with air-cooled condensers, its cooling effect is more stable in high-temperature environments, and the energy consumption is relatively low.

- Energy-saving operation: Due to the high-efficiency heat exchange characteristics of evaporative cooling, the energy consumption of the unit is reduced. Furthermore, during partial load operation, the energy regulation function of the screw compressor can automatically adjust the cooling capacity according to the actual load demand, avoiding unnecessary energy waste and further improving the energy efficiency of the unit.

2. Compact structure:

- Integrated design: The main components such as the screw compressor, evaporator, and evaporative condenser are integrated into one unit, reducing the floor space and installation space required. This integrated design makes installation and maintenance of the unit more convenient. Unlike traditional water-cooled chillers, it does not require separate cooling towers, cooling water pumps, etc., reducing installation costs and system complexity.

- Simplified piping: The integrated structural design reduces pipe connections and length, reducing pipe resistance loss and the risk of refrigerant leakage, improving system stability and reliability.

3. Stable and reliable operation:

- Superior screw compressor performance: Screw compressors have advantages such as simple structure, stable operation, low vibration, and low noise. Their unique working principle results in less compressor wear and a long service life. Screw compressors can operate stably within a wide load range, maintaining high efficiency even under low loads.

- Strong evaporative cooling adaptability: Evaporative condensers are highly adaptable to the environment and can operate stably under various climatic conditions. Even in areas with water shortages or poor water quality, the unit's normal refrigeration can be ensured. At the same time, the condenser surface of evaporative cooling is not prone to scaling, reducing the probability of reduced heat exchange efficiency and equipment failure caused by scaling.

- Multiple protection functions: The unit is usually equipped with complete protection devices, such as high and low-pressure protection, overload protection, overheat protection, and water shortage protection. It can monitor the operating status of the unit in real time. When an abnormality occurs, it will promptly alarm and automatically shut down to protect the safe operation of the unit.

4. Low maintenance cost:

- Easy-to-maintain structure: The integrated design makes the unit structure more compact, and the connections between the components are simpler, facilitating inspection and maintenance by maintenance personnel. At the same time, the structure of the evaporative condenser is relatively simple, and cleaning and maintenance are also relatively easy.

- Long-life components: The main components such as the screw compressor and evaporative condenser have a long service life, reducing the frequency of equipment replacement and maintenance costs. High-quality component materials and advanced manufacturing processes ensure the reliability and stability of the unit, reducing the failure rate of the equipment.

5. Wide range of applications:

- Suitable for various locations: Evaporative cooling screw chillers can be widely used in commercial buildings, industrial plants, hospitals, schools, hotels, and various other locations to meet the cooling needs of different locations. Whether it is a large central air conditioning system or a small process cooling system, evaporative cooling screw chillers can provide stable cooling effects.

- Low environmental requirements: Due to its structural and performance characteristics, evaporative cooling screw chillers have relatively low requirements for the installation environment and can be installed indoors, on rooftops, or in outdoor open spaces without site restrictions.

Keyword:

Previous Page

Next Page

Previous Page

Next Page

More Products

Inquire Now

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!

CN

CN EN

EN