Medium temperature series

0℃~30℃

The refrigeration range of the water-cooled variable frequency magnetic levitation chiller is 45-1600 tons (160-5625 kw), which is sufficient to meet the application needs of all industries today.

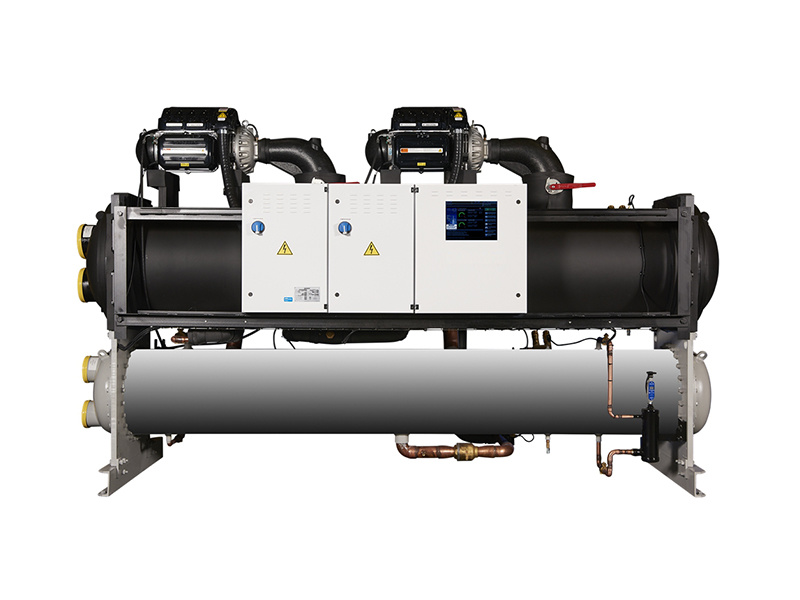

Water-cooled variable frequency magnetic levitation chiller

The water-cooled variable frequency magnetic levitation chiller unit has a cooling range of 45-1600 refrigeration tons (160-5625 kW), sufficient to meet the application needs of all industries today.

45-1600 refrigeration tons (160-5625 kW)

Magnetic levitation compressor: R1234ze, R515B, R513A and R134a

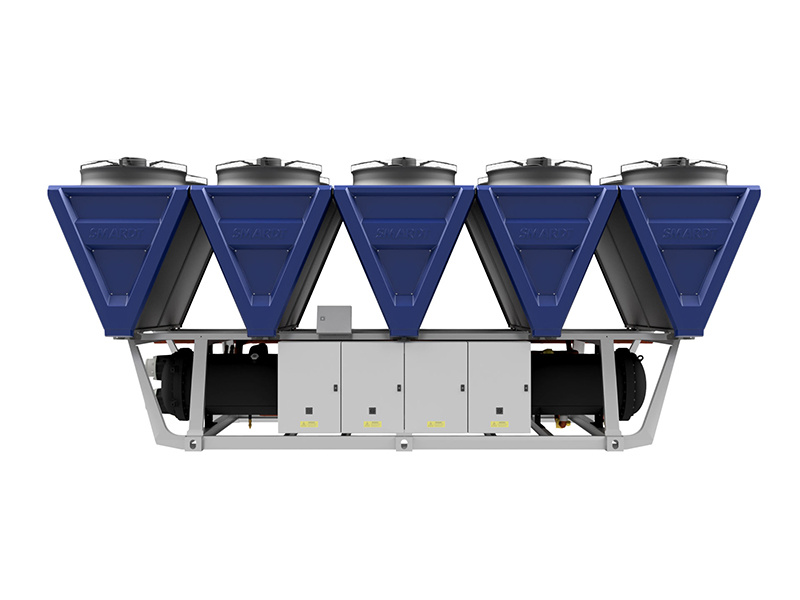

Air-cooled variable frequency magnetic levitation chiller

Quiet enough to hold a normal conversation even when the unit is running at full load!

30-520 refrigeration tons (105-1830 kW)

Oil-free magnetic bearing compressor: R1234ze, R515B, R513A and R134a

Groundbreaking low-noise and high-efficiency operation

Screw water-cooled chillers have the following main characteristics and advantages: high cooling efficiency, good heat exchange effect, convenient installation and maintenance

Air-cooled screw chiller (heat pump) unit

Using a screw compressor, it has high volumetric efficiency and energy conversion efficiency. Its unique rotor structure and operating principle can provide a large amount of refrigeration (heat) while consuming less electricity. Compared with other types of compressors, its energy efficiency is outstanding.

Evaporative air-cooled chiller

Evaporative-cooled screw chillers utilize evaporative condensers, which combine the advantages of water-cooled and air-cooled systems. A water film forms on the condenser surface, absorbing heat from the refrigerant through evaporation. Simultaneously, airflow carries away the water vapor produced by the evaporating film, resulting in highly efficient heat exchange. Compared to traditional water-cooled condensers, evaporative cooling offers higher heat transfer efficiency, providing greater cooling capacity at the same energy consumption. Compared to air-cooled condensers, it offers more stable cooling performance in high-temperature environments and relatively lower energy consumption.

Naturally cooled air-cooled chiller

In low ambient temperatures, the unit can use natural cold sources for cooling, reducing or completely avoiding the operation of the compressor, thus significantly reducing energy consumption. For example, during the transition seasons and winter, when the outdoor temperature reaches certain conditions, the natural cooling system starts to work, sharing the refrigeration load, and the energy saving effect is significant. Compared with traditional air-cooled screw chillers, the natural cooling function can effectively reduce operating costs.

Water-cooled industrial chiller

Employing a scroll compressor, its unique operating principle makes the gas compression process more continuous and stable, reducing energy loss. Compared to traditional reciprocating compressors, scroll compressors can improve efficiency by more than 10%, providing greater cooling capacity while consuming less electricity, thus lowering operating costs.

Water-cooled open industrial chiller

Equipped with high-efficiency shell and tube condensers and evaporators. The condenser can quickly transfer heat from the refrigerant to the cooling water, and the evaporator allows the refrigerant to fully evaporate and absorb heat, achieving efficient heat exchange. This structural design results in higher refrigeration efficiency for the chiller, enabling it to quickly lower the water temperature to the required level, meeting the needs of rapid cooling in industrial production.

The unit adopts a box-type structure, integrating the compressor, evaporator, condenser, water pump, water tank and other components into a single box. The layout is reasonable, space-saving, and easy to install and arrange in various industrial locations, especially suitable for workshops and laboratories with limited space.

CN

CN EN

EN