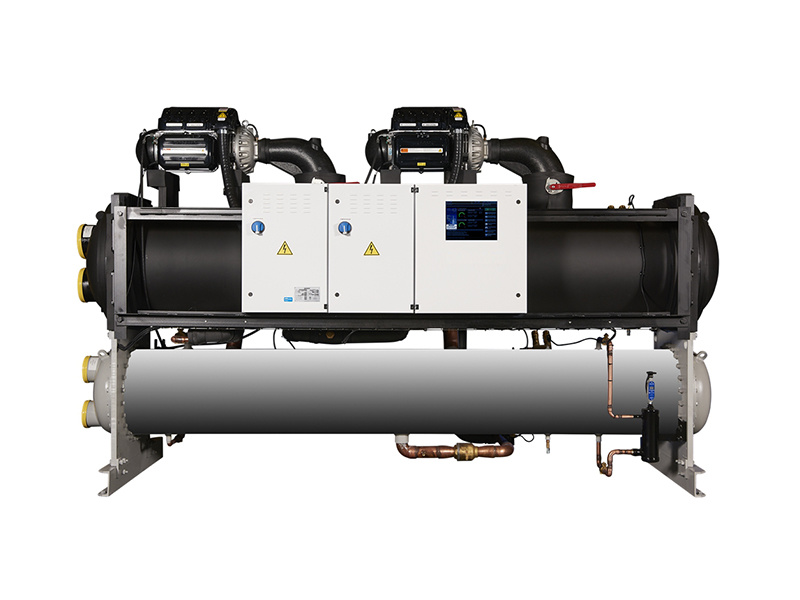

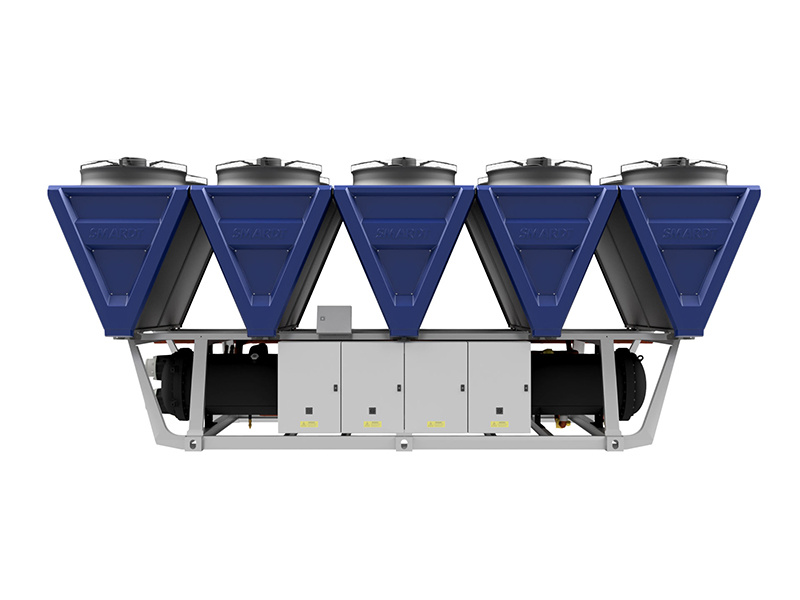

Medium and low temperature evaporative screw chiller

Efficient Compression Process: The screw compressor in a screw chiller consists of two rotating components: a main screw and an auxiliary screw. After the refrigerant is drawn in, it is gradually compressed as the screws rotate, forming high-temperature, high-pressure gas. This compression method is continuous and smooth, and the gas is compressed relatively uniformly, allowing the unit to maintain high efficiency during operation.

- Cooling capacity range: 70KW to 1500KW

- Temperature control range: 0℃ to -35℃

- Temperature control accuracy: ±1℃

- Optional refrigerants: R22, R404A, R407C, R507A

- Installation environment: Outdoor installation

- Non-standard customization: Explosion-proof type, corrosion-resistant type

- Optional: MODBUS RTU protocol RS485 remote communication, energy-saving frequency conversion

Category:

Medium low temperature series

Product Attachment:

Medium and low temperature evaporative cooling screw chiller units have the following characteristics and advantages:

Characteristics:

1. In terms of working principle:

- Efficient compression process: The screw compressor in a screw chiller unit consists of two rotating components: a main screw and an auxiliary screw. After the refrigerant is sucked in, it is gradually compressed as the screw rotates, forming a high-temperature and high-pressure gas. This compression method is continuous and stable, and the gas is compressed relatively evenly, allowing the unit to maintain high efficiency during operation.

- Sufficient heat exchange: After the high-temperature and high-pressure gas enters the evaporative condenser, it exchanges heat with a mixed medium of external air and water. The unique design of the evaporative condenser allows the refrigerant to dissipate heat sufficiently, quickly cool, and transform into a high-pressure liquid. After the high-pressure liquid is depressurized by the expansion valve, it enters the evaporator, absorbs heat from the cooled object in the evaporator, and achieves a cooling effect.

2. In terms of structural design:

- High integration: Key components such as the screw compressor, evaporative condenser, evaporator, and expansion valve are integrated into one unit, resulting in a compact structure, reduced floor space, and convenient installation and placement in various locations.

- Simple connecting pipes: Internal pipe connections are optimized to reduce pipe length and the number of bends, reducing refrigerant pressure loss in the pipes and improving system cooling efficiency.

Advantages:

1. Strong refrigeration performance:

- Excellent low-temperature refrigeration capacity: It can operate stably in the medium and low temperature range of 0℃~-35℃, meeting the low-temperature refrigeration needs of industries such as chemical, pharmaceutical, and food processing. For example, in the pharmaceutical industry, the production and storage of some medicines require low-temperature environments, and this unit can provide reliable refrigeration support2.

- Large refrigeration capacity: The screw compressor has a large exhaust volume and a high compression ratio, allowing the unit to output a large amount of cooling capacity, suitable for large-scale industrial refrigeration and central air conditioning systems with high cooling capacity requirements.

2. Energy-efficient and efficient:

- Evaporative cooling technology saves energy: The evaporative condenser combines the advantages of air cooling and water cooling, utilizing the latent heat of water evaporation to absorb the heat of the refrigerant. Compared with traditional air-cooled or water-cooled condensers, it can significantly reduce energy consumption. Moreover, evaporative cooling technology requires less circulating water, reducing water pump energy consumption.

- High screw compressor efficiency: The screw compressor has low frictional losses between moving parts and high mechanical efficiency, enabling high cooling capacity output with low energy consumption. At the same time, the unit's control system can automatically adjust the compressor's operating frequency according to the actual load, further improving energy utilization.

3. Stable and reliable operation:

- Reliable component quality: High-quality screw compressors, evaporative condensers, and other components are used. These components have good corrosion resistance and wear resistance, allowing them to operate stably for a long time in harsh working environments. For example, the shell of the evaporative condenser is usually made of corrosion-resistant materials to withstand external environmental erosion.

- Low operating noise: The screw compressor operates smoothly with low vibration, and the reasonable sound insulation design ensures that the noise generated during operation is low and does not cause significant interference to the surrounding environment.

4. Convenient maintenance and management:

- Structure convenient for maintenance: The unit's structure is reasonably designed, and the layout of the components is compact, making it convenient for maintenance personnel to carry out daily inspections, maintenance, and repair work. For example, cleaning and maintenance of the evaporator and condenser are relatively convenient, allowing for regular cleaning to maintain good heat exchange efficiency.

- Intelligent control system: Equipped with an advanced intelligent control system, it can monitor the unit's operating status in real time, automatically diagnose faults and issue alarm signals, allowing users to promptly discover and solve problems. At the same time, the control system can also record the unit's operating data, providing users with data analysis and management.

Keyword:

Previous Page

Previous Page

Next Page

More Products

Inquire Now

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!

CN

CN EN

EN