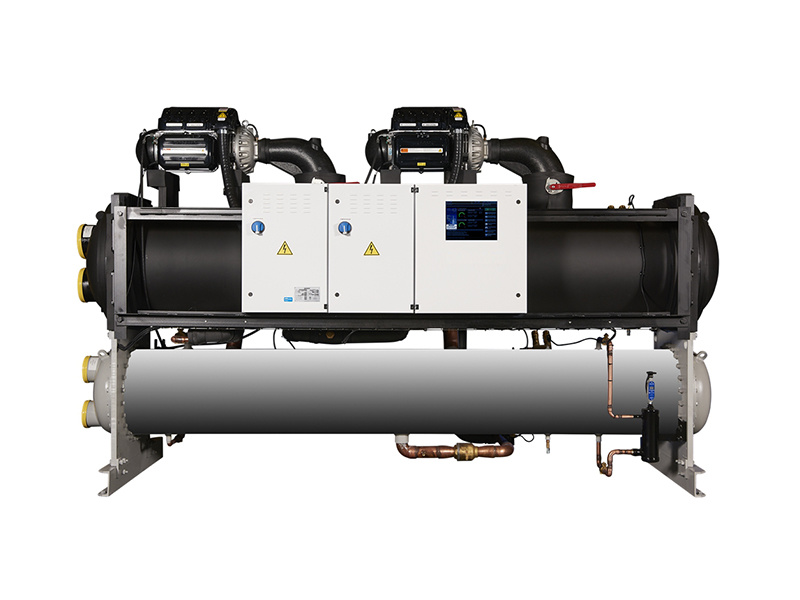

Low-temperature single-unit double-stage chiller

Unique single-unit, two-stage structure: This chiller adopts a single-unit, two-stage compression technology, featuring two compression stages. The refrigerant undergoes intermediate cooling after the first stage of compression before entering the second stage. This structure effectively increases the refrigerant's pressure and temperature range, enabling highly efficient refrigeration in ultra-low temperature environments. Compared to single-stage compression, it offers higher cooling capacity and better performance under low-temperature conditions.

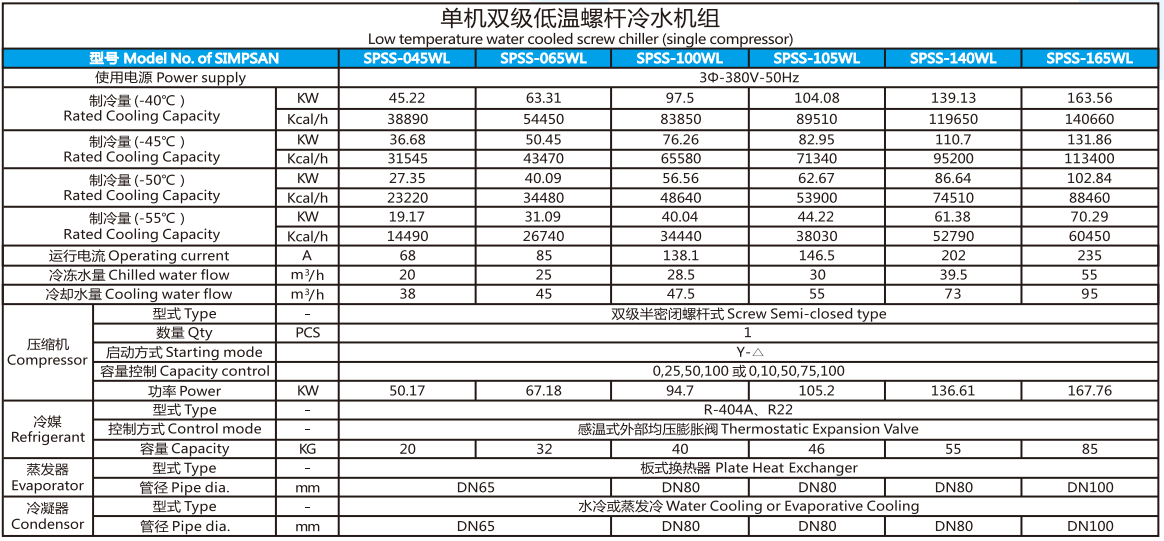

- Cooling capacity range: 60KW to 210KW

- Temperature control range: -40℃ to -60℃

- Temperature control accuracy: ±1℃

- Refrigerant options: R22, R404A, R507A

- Installation environment: Indoor installation

- Non-standard customization: Explosion-proof type, corrosion-resistant type

- Optional: MODBUS RTU protocol RS485 remote communication

Category:

Low temperature series

Product Attachment:

The single-unit, two-stage, low-temperature, water-cooled chiller unit has the following characteristics and advantages:

Characteristics:

1. Compressor structure and operating mode:

Unique single-unit, two-stage structure: This chiller unit adopts single-unit, two-stage compression technology, with two compression stages. The refrigerant is intercooled after the first stage of compression before entering the second stage. This structure effectively improves the pressure and temperature change range of the refrigerant, enabling efficient refrigeration in ultra-low temperature environments. Compared to single-stage compression, it provides higher refrigeration capacity and better performance under low-temperature conditions.

High demands on the compressor: Equipped with compressors specially designed for low-temperature conditions, the materials and processing techniques of its components can withstand extreme low-temperature environments. For example, key components of the compressor, such as seals and bearings, must have good low-temperature resistance to ensure normal operation at ultra-low temperatures.

2. Compatibility of refrigerant and coolant:

Strict refrigerant selection: Uses refrigerants suitable for ultra-low temperature conditions, such as R404A, R23, etc. These refrigerants have low evaporation temperatures and high refrigeration efficiency, meeting the low-temperature refrigeration needs of -40℃~-60℃, while also complying with environmental requirements.

Diversity of coolants: Various coolants can be selected based on different application scenarios and needs, such as ethylene glycol aqueous solutions, alcohol, ternary mixed solutions and other alcohol-based coolants, or calcium chloride aqueous solutions. The selection of coolant needs to consider factors such as its freezing point, specific heat capacity, and corrosiveness to ensure normal flow and effective heat transfer at low temperatures.

3. High efficiency of the heat exchange system:

High-efficiency heat exchanger design: Both the evaporator and condenser adopt high-efficiency heat exchange design, such as using high-efficiency finned tubes, spiral tubes, etc., to increase the heat exchange area and improve the heat exchange efficiency. At the same time, the optimized heat exchange tube layout and fluid flow path can reduce flow resistance and lower energy consumption.

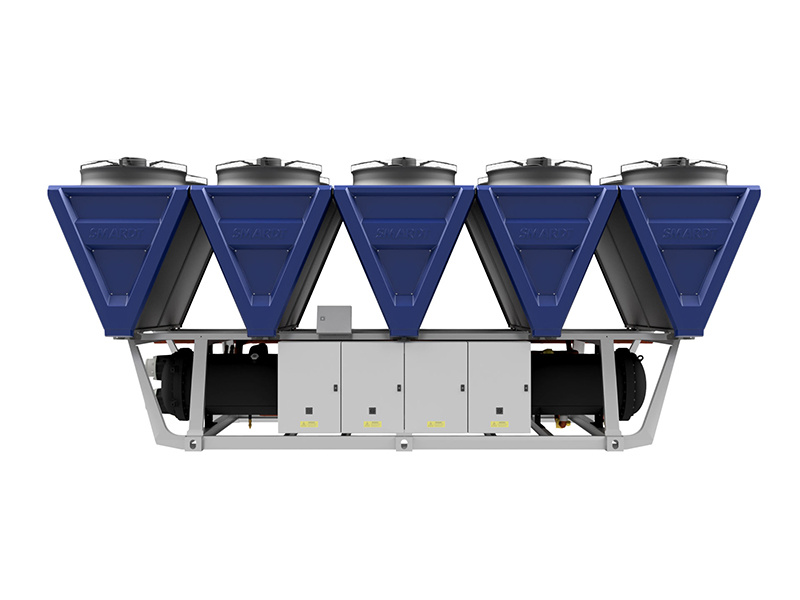

Advantages of water-cooled cooling: Water is used as the cooling medium, and the refrigerant in the condenser is cooled by equipment such as cooling towers. Water has a large specific heat capacity and can absorb a large amount of heat, ensuring that the refrigerant can quickly dissipate heat during the condensation process, improving the overall performance of the refrigeration system. Furthermore, the water-cooled cooling method is relatively less affected by ambient temperature and can maintain good cooling effects even in high-temperature environments.

4. Precision of the control system:

Intelligent and precise control: Equipped with an advanced intelligent control system that can monitor the operating parameters of the chiller unit in real-time, such as temperature, pressure, and flow rate, and automatically adjust the compressor's operating frequency and refrigerant flow rate according to the preset program to ensure that the unit maintains a stable operating state under different loads. For example, when the refrigeration demand decreases, the control system can automatically reduce the compressor's operating frequency to achieve energy-saving operation.

High-precision temperature control: It has high-precision temperature control capabilities, capable of precisely controlling the outlet temperature within the range of -40℃~-60℃, meeting the extremely strict temperature control requirements of some processes, such as in the fields of biopharmaceuticals and low-temperature testing of chemical materials.

5. Comprehensiveness of safety protection:

Multiple protection mechanisms: Multiple safety protection devices are set up, including high and low pressure protection, anti-freeze protection, overheating protection, overload protection, phase-loss protection, and reverse-phase protection. When the unit encounters an abnormal situation, it can automatically shut down and issue an alarm signal in a timely manner to protect the safe operation of the unit. For example, in winter or low-temperature environments, the anti-freeze protection device can prevent the water system from freezing, avoiding equipment damage.

Reliable oil return system: For screw-type chiller units, the oil return system is crucial. This unit is equipped with an intelligent oil return control system to ensure that the compressor can promptly recover the refrigeration oil during operation, ensuring the lubrication effect of the compressor and extending its service life.

Advantages:

1. Powerful refrigeration performance:

Ultra-low temperature refrigeration capability: It can operate stably in an extremely low-temperature environment of -40℃~-60℃, providing reliable refrigeration effects and meeting the ultra-low temperature refrigeration needs of some special industries, such as biopharmaceuticals, food freezing, and low-temperature testing of chemical materials.

High refrigeration capacity output: The single-unit, two-stage structure and the high-efficiency compressor design enable the chiller unit to output a large refrigeration capacity, suitable for large cold storage facilities, frozen processing production lines, and other places with high refrigeration capacity requirements.

2. High efficiency and energy saving:

Significant energy-saving effect of two-stage compression: Single-unit, two-stage compression technology can improve the compression efficiency of the refrigerant and reduce the energy consumption of the compressor. Compared with single-stage compression, under the same refrigeration capacity, two-stage compression has lower energy consumption, thus reducing operating costs.

Optimized system design for energy saving: Through optimized design of the heat exchange system, refrigerant circulation system, etc., energy loss is reduced, and the energy utilization rate of the entire chiller unit is improved. For example, reasonable pipeline layout and pipe diameter selection can reduce pressure loss of the refrigerant in the pipes; high-efficiency condenser and evaporator designs can improve heat exchange efficiency and reduce energy consumption.

3. Stable and reliable operation:

High-quality components guarantee: High-quality compressors, heat exchangers, controllers, and other components are used. These components have good low-temperature performance and reliability, ensuring the stability of the chiller unit during long-term operation. For example, the compressor has good sealing performance to prevent refrigerant leakage; the material of the heat exchanger is corrosion-resistant and can work in a low-temperature water environment for a long time.

Good environmental adaptability: It has good adaptability to environmental temperature, water quality, and other factors. Under different environmental conditions, the refrigeration unit can maintain stable operating performance and is not affected by the external environment. At the same time, for areas with poor water quality, appropriate refrigerants can be selected and corresponding water treatment measures can be taken to ensure the normal operation of the refrigeration unit.

4. Convenient maintenance and management:

Compact structure for easy maintenance: The overall structure is compact and has a small footprint, making it easy to install and arrange. At the same time, the connections between the components are tight, reducing the probability of pipe leakage and other failures. Furthermore, the design of some key components makes them easy to disassemble and replace, reducing maintenance costs and downtime.

Intelligent control system assists maintenance: The intelligent control system can automatically diagnose faults and provide detailed fault information, facilitating maintenance personnel in repairs and maintenance. Maintenance personnel can use the control system display screen or remote monitoring system to understand the operating status of the unit in real time, promptly discovering and solving problems.

The Double-Stage Low Temperature Chiller represents a pinnacle of engineering for demanding industrial and laboratory applications. Its core innovation lies in its unique dual-stage refrigeration circuit, which enables it to achieve and maintain exceptionally low temperatures with remarkable stability. This system is specifically engineered to handle high heat load removal requirements where conventional single-stage chillers fall short. The robust design ensures reliable performance even under the most strenuous operating conditions.

At the heart of its superior performance is the advanced double-stage compression process. This sophisticated mechanism allows the Double-Stage Low Temperature Chiller to operate efficiently across a wide temperature range. By separating the compression into two distinct phases, the system reduces the workload on individual components, enhancing overall durability and energy efficiency. This design is crucial for processes that require precise thermal management at sub-ambient temperatures, guaranteeing consistent results.

This chiller is the ideal solution for a multitude of critical processes. It is perfectly suited for applications in chemical synthesis, pharmaceutical production, and vacuum trap cooling, where precise low-temperature control is non-negotiable. The unparalleled cooling capacity of this Double-Stage Low Temperature Chiller makes it indispensable for pilot plants and research facilities. Its ability to provide stable refrigeration ensures the integrity and repeatability of sensitive experiments and production batches.

Investing in our Double-Stage Low Temperature Chiller translates to long-term operational reliability and significant cost savings. The efficient two-stage design minimizes energy consumption while maximizing cooling power. With user-centric features such as intuitive controls and comprehensive safety protections, this system simplifies complex temperature management. Choose our advanced Double-Stage Low Temperature Chiller to elevate the precision, efficiency, and reliability of your critical cooling processes.

Previous Page

More Products

Inquire Now

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!

CN

CN EN

EN