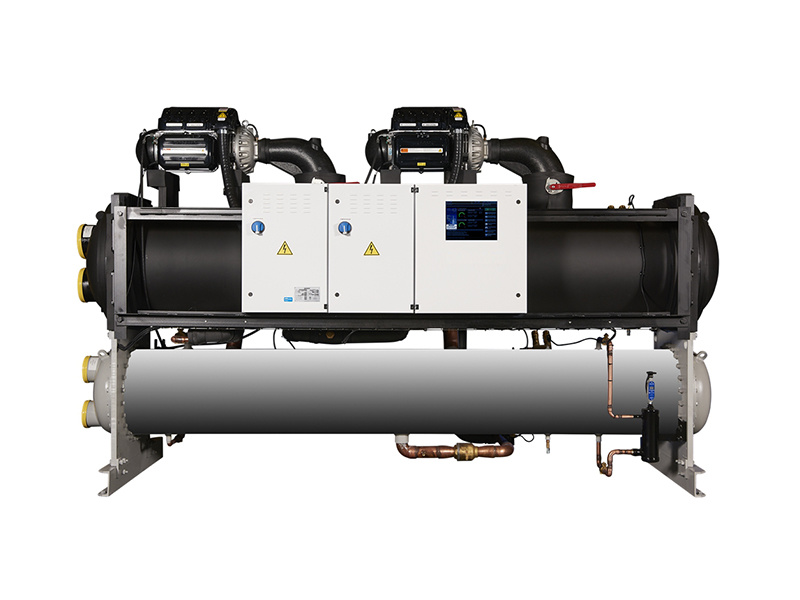

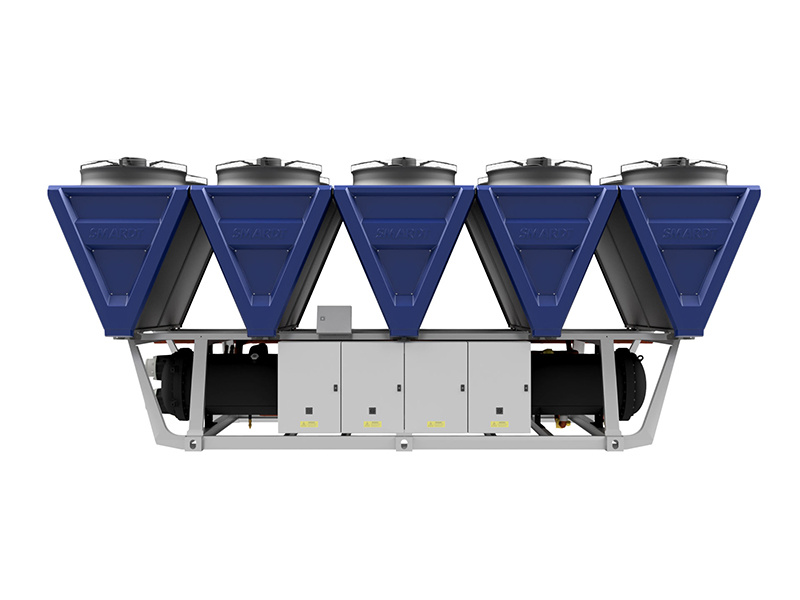

Ultra-low temperature cascade cryogenic unit

Multi-stage refrigeration cycle: Composed of two or more independent refrigeration cycles, a high-temperature stage and a low-temperature stage. The high-temperature refrigeration system uses a medium-temperature refrigerant to first transfer heat to the low-temperature system; the low-temperature refrigeration system uses a low-temperature refrigerant to further lower the temperature to an ultra-low temperature range. For example, common high-temperature refrigerants include R404A and R22, while common low-temperature refrigerants include R23 and R14.

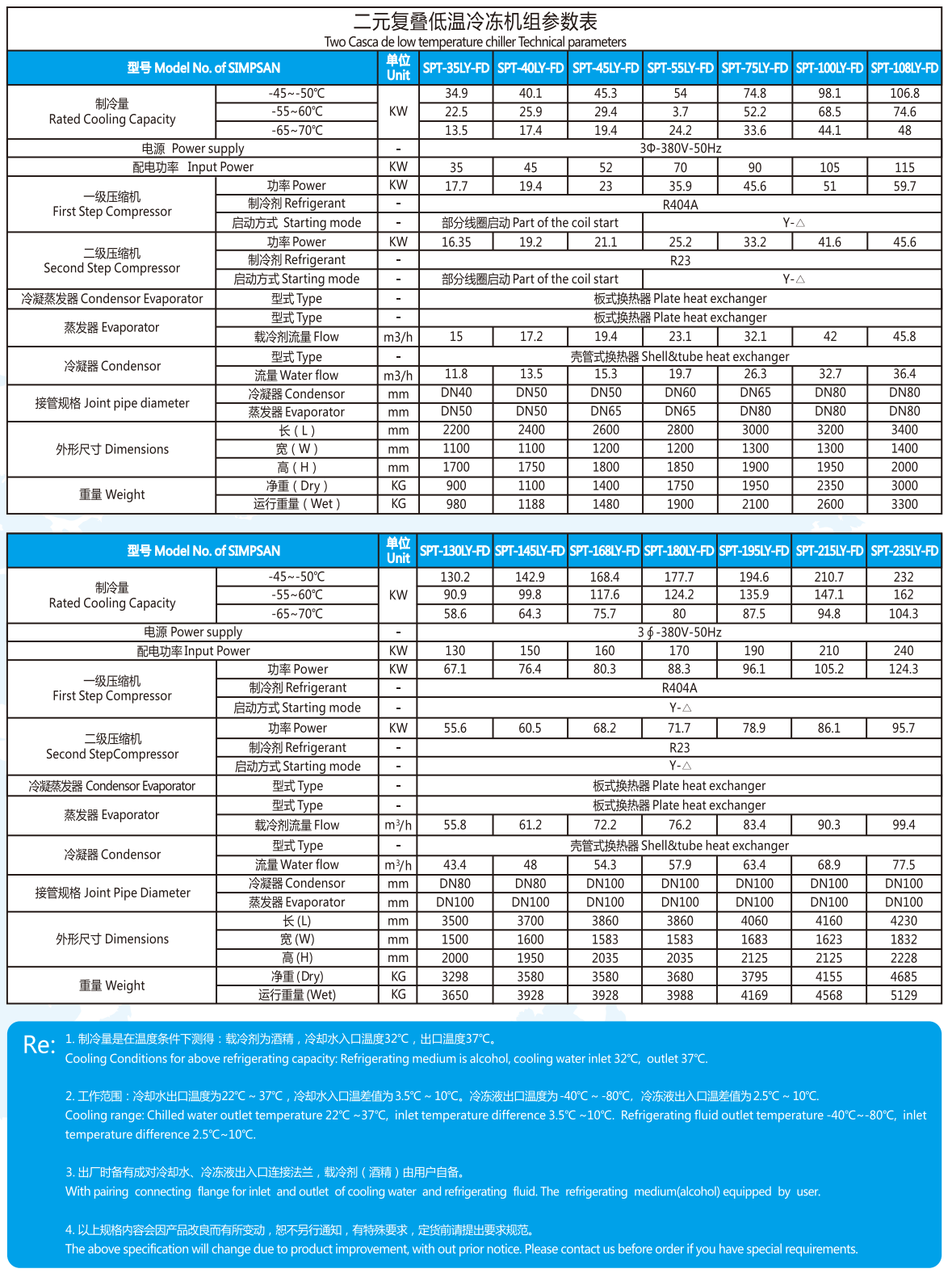

- Cooling capacity range: 60KW to 210KW

- Temperature control range: -50℃ to -135℃

- Temperature control accuracy: ±1℃

- Optional refrigerants: R404A, R507A, R23, R508B

- Installation environment: Indoor installation

- Non-standard customization: Explosion-proof type, corrosion-resistant type

- Optional: MODBUS RTU protocol RS485 remote communication

Category:

Ultra low temperature series

Product Attachment:

The main characteristics and advantages of ultra-low temperature cascade cryogenic units are as follows:

Characteristics:

1. Complex system structure:

- Multi-stage refrigeration cycle: It consists of two or more independent refrigeration cycles, a high-temperature stage and a low-temperature stage. The high-temperature refrigeration system uses a medium-temperature refrigerant to first transfer heat to the low-temperature system; the low-temperature refrigeration system uses a low-temperature refrigerant to further reduce the temperature to the ultra-low temperature range. For example, common high-temperature refrigerants include R404A and R22, and low-temperature refrigerants include R23 and R14.

- Intermediate heat exchanger: Equipped with a condenser evaporator, this is a key component of the cascade cryogenic unit, serving as both the evaporator for the high-temperature stage and the condenser for the low-temperature stage. It enables heat exchange between the high-temperature and low-temperature refrigerants, allowing the low-temperature refrigerant to condense at a lower temperature, thus ensuring the refrigeration effect of the low-temperature stage.

- High-precision temperature control: The temperature can be precisely controlled within the ultra-low temperature range of -50℃~-135℃, with high control accuracy, generally reaching ±1℃ or even higher. This is very important for applications with extremely strict temperature requirements, such as superconductor research and biological product storage.

2. Special compressor design:

- Low-temperature resistance: The compressor needs to have good low-temperature resistance. Its internal components, such as bearings and seals, use special materials and designs to ensure normal operation in ultra-low temperature environments.

- High compression ratio: To achieve ultra-low temperature refrigeration, the compressor needs to have a high compression ratio, able to compress the refrigerant to a sufficiently high pressure so that it can evaporate and absorb heat at low temperatures, thereby achieving refrigeration.

- Suitable refrigerant selection: Use refrigerants suitable for ultra-low temperature conditions. These refrigerants have low evaporation temperatures and high refrigeration efficiency, and can exhibit good refrigeration performance in ultra-low temperature environments. The selection of refrigerants also needs to consider their environmental friendliness and safety.

3.A comprehensive security protection system:

- Pressure protection: High-pressure and low-pressure protection devices are set. When the system pressure is too high or too low, it can automatically shut down to protect the safe operation of the unit. For example, in the low-temperature system, if the refrigerant pressure is too low, the compressor may not work properly; if the pressure is too high, the equipment may be damaged.

- Temperature protection: It has temperature sensors and controllers that can monitor the system temperature in real time. When the temperature exceeds the set range, it will automatically alarm and take corresponding protective measures, such as stopping the compressor.

- Other protections: It also includes overload protection, phase loss protection, and reverse phase protection to ensure that the unit can stop running in time under various abnormal conditions, preventing equipment damage.

Advantages:

1. High-efficiency refrigeration performance:

- Strong low-temperature refrigeration capacity: It can provide stable refrigeration effects in extremely low-temperature environments, meeting the needs of industries requiring ultra-low temperature refrigeration, such as pharmaceuticals, chemicals, and scientific research. For example, in pharmaceutical manufacturing, some biological products need to be stored at ultra-low temperatures, and cascade cryogenic units can provide the required low-temperature environment.

- Relatively high energy efficiency ratio: Through reasonable system design and refrigerant selection, cascade cryogenic units can maintain a high energy efficiency ratio while performing ultra-low temperature refrigeration, reducing operating costs. Compared with other low-temperature refrigeration methods, cascade cryogenic units have relatively low energy consumption under the same refrigeration capacity.

2. Stable and reliable operation:

- Independent refrigeration systems: The high-temperature and low-temperature systems are relatively independent. Even if one system malfunctions, the other system can still continue to operate, ensuring the overall operational stability of the unit. This independent system design also facilitates maintenance and repair.

- Good adaptability: It has strong adaptability to environmental temperature, humidity, and other conditions, and can operate stably in different environments. Even under harsh environmental conditions such as high temperature and high humidity, cascade cryogenic units can maintain good refrigeration performance.

3. Flexible range of applications:

- Multiple application scenarios: Widely used in chemical industry, pharmaceutical manufacturing, research laboratories, food processing, and various ultra-low temperature laboratories and low-temperature cold sources.

- High degree of customization: Because different application scenarios have different requirements for temperature, refrigeration capacity, and other parameters, cascade cryogenic units can be customized according to user needs to meet various special application requirements.

An ultra-low temperature cascade chiller is a specialized cooling system designed to achieve temperatures far below the typical capabilities of standard refrigeration units. These chillers are specifically engineered to handle temperatures down to -80°C or even lower, making them essential for industries that require precise temperature control in extremely cold environments. Ultra-low temperature cascade chillers are commonly used in fields such as scientific research, medical applications, and industrial processes that demand ultra-cold conditions for optimal results.

The key feature of an ultra-low temperature cascade chiller is its dual-stage cooling system. It utilizes two distinct refrigeration circuits that operate in series, with each circuit cooling the refrigerant to progressively lower temperatures. This cascade system ensures that the ultra-low temperatures can be reached efficiently and maintained consistently, providing stable cooling even under demanding conditions. The use of high-quality compressors, heat exchangers, and refrigerants contributes to the chiller's exceptional performance and energy efficiency.

One of the main advantages of the ultra-low temperature cascade chiller is its versatility. It can be used for a wide range of applications, including cooling laboratory equipment, preserving sensitive biological samples, and supporting cryogenic research. Additionally, its ability to maintain precise temperature settings ensures that temperature-sensitive materials remain safe and effective throughout the cooling process. The system's advanced control features, such as temperature monitoring and alarm systems, provide users with complete control and peace of mind.

In conclusion, an ultra-low temperature cascade chiller is a powerful and reliable cooling solution that delivers precise temperature control for a wide variety of specialized applications. Its dual-stage cooling system, energy efficiency, and versatility make it a valuable asset in industries that require ultra-cold conditions.

Previous Page

More Products

Inquire Now

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!

CN

CN EN

EN