china variable frequency centrifugal chiller

2025-07-16 14:27

Overall Efficiency Improvement 50%

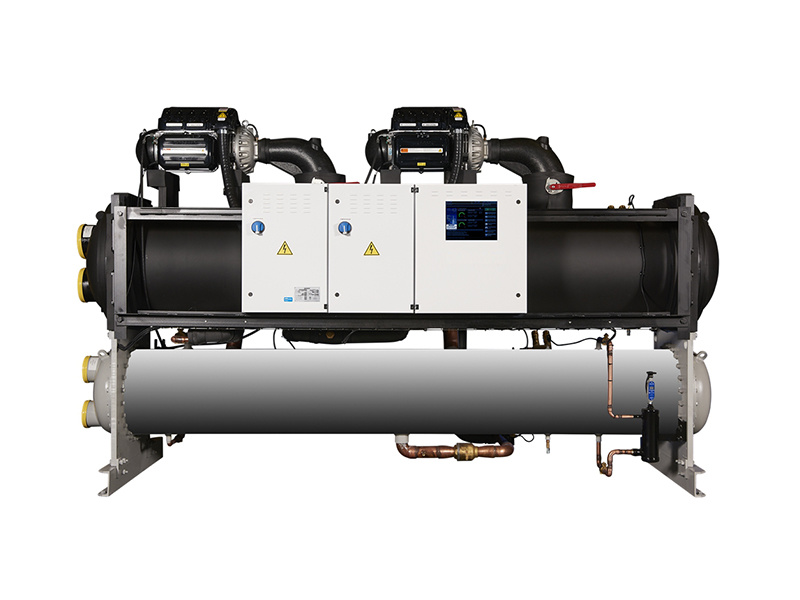

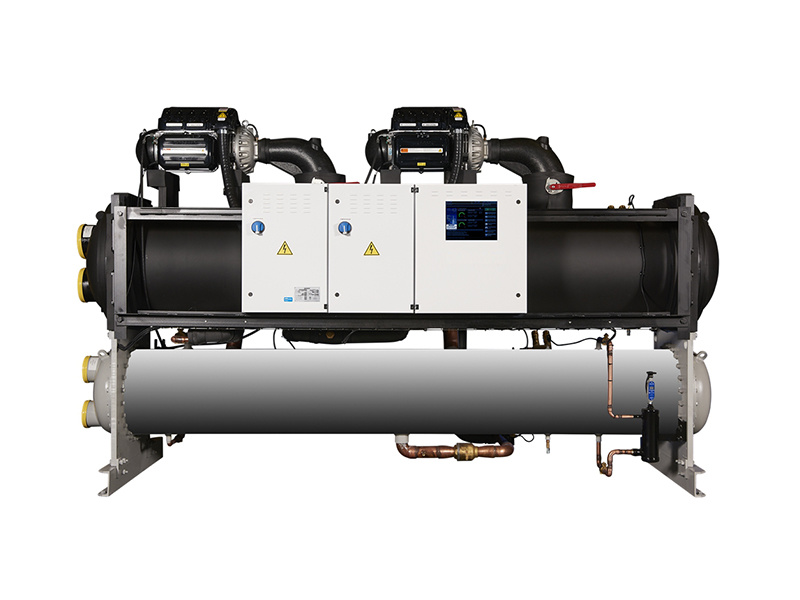

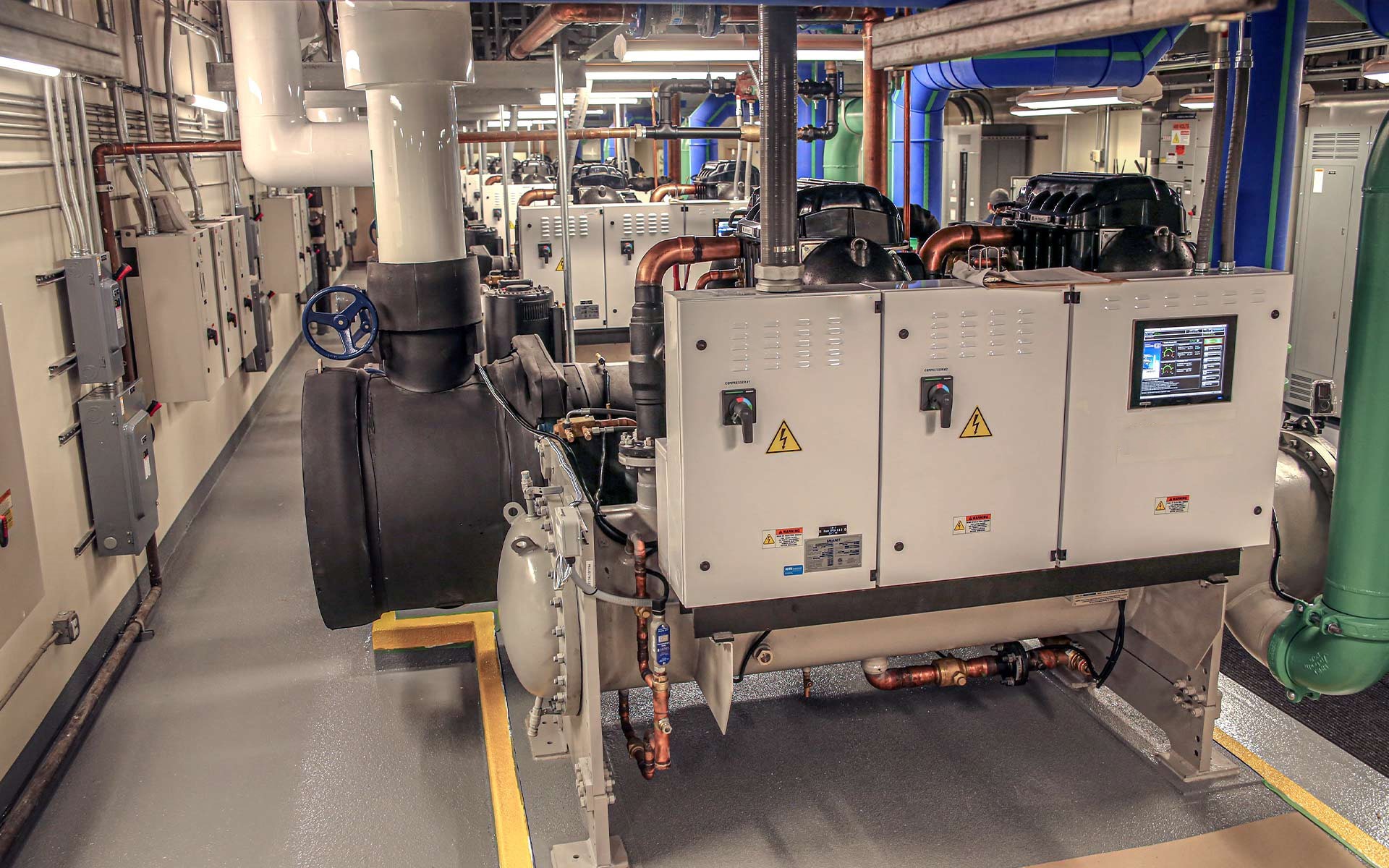

The water-cooled variable frequency magnetic levitation chiller has a cooling capacity range of 45-1600 refrigeration tons (160-5625 kW), sufficient to meet the application needs of all industries today.

The variable frequency centrifugal chiller represents a significant leap forward in cooling technology, offering unmatched energy efficiency for large-scale applications. This chiller operates by adjusting the compressor speed according to the specific cooling needs, making it a smart choice for energy-conscious businesses. With the variable frequency centrifugal chiller, users can reduce their energy consumption without sacrificing performance, leading to substantial cost savings in the long term.

One of the standout features of the variable frequency centrifugal chiller is its ability to maintain stable cooling performance under varying load conditions. By continuously adjusting to changing demands, the chiller ensures that only the necessary energy is used, avoiding overcooling and minimizing waste. This dynamic adjustment results in improved overall system efficiency and better environmental sustainability.

The variable frequency centrifugal chiller is designed with reliability and ease of use in mind. Its intuitive control systems and user-friendly interface make it easy to operate and maintain. Additionally, its robust construction ensures that it can withstand the rigors of continuous operation, providing long-lasting reliability for a wide range of applications.

Ideal for industries such as commercial real estate, manufacturing, and data processing, the variable frequency centrifugal chiller provides an adaptable, high-performance cooling solution. By choosing this advanced system, businesses can not only improve their cooling efficiency but also contribute to reducing their carbon footprint, making it an ideal choice for those seeking both performance and environmental responsibility.

45-1600 refrigeration tons (160-5625 kW)

Magnetic Levitation Compressor:

R1234ze, R515B, R513A and R134a

High Efficiency and Energy Saving

High Energy Efficiency Ratio

Magnetic bearing technology eliminates the frictional losses of traditional mechanical bearings, significantly improving the unit's mechanical efficiency. Combined with variable frequency technology, it can flexibly adjust the compressor speed according to the actual load demand, maintaining efficient operation under different loads. The integrated part load performance coefficient (IPLV) is high, with the IPLV of some products as high as 10 or more, and the energy efficiency advantage at part load is even more obvious.

Stable and Reliable Operation

Magnetic Levitation Bearing Support

Magnetic bearings use electromagnetic force to levitate the compressor rotor in the air, avoiding the wear and tear and friction of traditional mechanical bearings and the resulting mechanical failures. This contactless support method ensures smooth compressor operation, minimal vibration, and low noise levels, effectively extending the service life of the unit.

Precise Control Technology

Equipped with an advanced control system, it monitors the operating status of the unit in real time, precisely controlling parameters such as compressor speed and refrigerant flow to ensure stable operation of the unit under various operating conditions. It also has fault self-diagnosis and warning functions to detect and handle potential problems in a timely manner.

Strong Surge Protection Capability

The compressor control module has a control curve for safe operation of the compressor. By monitoring the operating status in real time and calculating and judging, it adjusts the speed in time to ensure that the compressor always operates within the safe zone, avoiding surge damage to the unit.

Environmentally Friendly Refrigerant

Usually uses green and environmentally friendly refrigerants, such as HFC-134a, which do not damage the ozone layer and meet environmental protection requirements.

Low Starting Current

The starting current of the magnetic levitation compressor is very small, only a fraction of that of a traditional compressor, or even lower. This has minimal impact on the power grid, helping to reduce grid load fluctuations and lower requirements and investment in power equipment.

Flexible Capacity Adjustment

It has a wide capacity adjustment range, generally achieving stepless adjustment from 10% to 100%. It can precisely adjust the cooling capacity according to the actual load demand, avoiding energy waste and meeting the load changes in different scenarios.

Compact Structure

The unit has a compact structure design, small footprint, saving installation space, and easy installation in different locations.

Low-Noise Operation

Due to the frictionless operation of magnetic bearings and advanced noise reduction technology, the unit operates at a very low noise level, typically around 77dB(A) or even lower, providing users with a quiet working and living environment.

Intelligent Communication

Communication usually uses advanced communication protocols, such as Modbus, to enable two-way data exchange with the user's automatic control system, facilitating remote monitoring and management by the user.

Previous: Understanding Variable Frequency Centrifugal Chillers: A Comprehensive Overview

More Information

2026-03-02

Understanding the Advantages of Water-Cooled Screw Chillers for Industrial Applications

2026-02-24

quality air cooled industrial chiller

2026-02-23

Essential Insights into Air Cooled Industrial Chillers: Efficiency, Selection, and Maintenance

2026-02-16

What to Expect During the Installation of Air Cooled Industrial Chillers: A Comprehensive Guide

2026-03-02

Understanding the Advantages of Water-Cooled Screw Chillers for Industrial Applications

CN

CN EN

EN