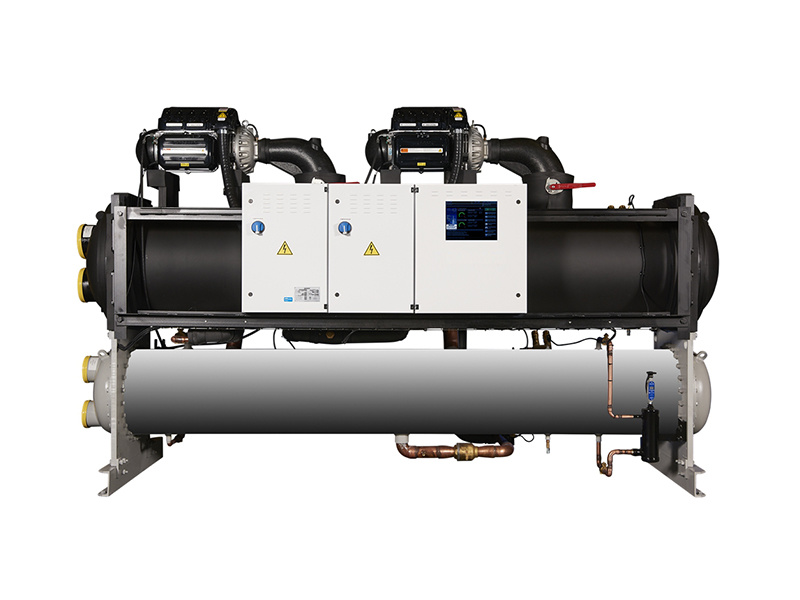

Water-cooled industrial chiller

Employing a scroll compressor, its unique operating principle makes the gas compression process more continuous and stable, reducing energy loss. Compared to traditional reciprocating compressors, scroll compressors can improve efficiency by more than 10%, providing greater cooling capacity while consuming less electricity, thus lowering operating costs.

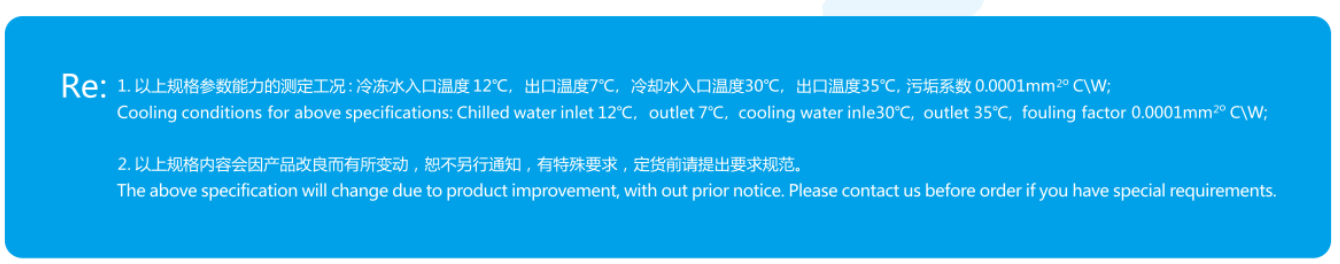

- Cooling capacity range: 10KW to 240KW

- Temperature control range: 5℃ to 30℃

- Temperature control accuracy: ±1℃

- Optional refrigerants: R22, R410A, R407C, R134a

- Installation environment: Indoor installation

- Non-standard customization: Explosion-proof, corrosion-resistant

- Optional: MODBUS RTU protocol RS485 remote communication, energy-saving frequency conversion

Category:

Medium temperature series

Product Attachment:

Water-cooled vortex industrial chillers have the following features and advantages:

1. High efficiency and energy saving:

- High compressor efficiency: Using a vortex compressor, its unique working principle makes the gas compression process more continuous and stable, reducing energy loss. Compared with traditional reciprocating compressors, the efficiency of vortex compressors can be improved by more than 10%, providing a large cooling capacity with less energy consumption, thereby reducing operating costs.

- High heat exchange efficiency: Equipped with a high-efficiency water-cooled condenser and evaporator. The condenser adopts a shell-and-tube structure, with stable heat transfer performance and a large heat transfer coefficient on the water side, which can quickly transfer the heat in the refrigerant to the cooling water; the evaporator usually uses reinforced copper tubes inside, with uniform refrigerant distribution, which can enhance the heat transfer effect and improve the heat exchange efficiency.

- Good partial load performance: During partial load operation, the vortex compressor can automatically adjust the output power according to the actual needs, avoiding unnecessary energy consumption. For example, when the cooling demand of the equipment is reduced, the compressor can correspondingly reduce the cooling capacity output and maintain efficient operation.

2. Reliable and stable operation:

- Superior compressor performance: The vortex compressor has a simple structure and few moving parts, without reciprocating pistons and connecting rods, so it has low mechanical vibration, low noise, low wear, reliable operation, and a long service life. Its operating time can reach more than 100,000 hours, greatly reducing equipment maintenance costs and downtime risks.

- Multiple protection functions: It has complete protection devices, such as high and low pressure protection, freezing protection for chilled water, power phase sequence protection, phase loss protection, insufficient water flow protection, and compressor motor overheating protection. These protection functions can monitor the operating status of the unit in real time. When an abnormality occurs, it will alarm and automatically shut down to ensure the safe operation of the unit.

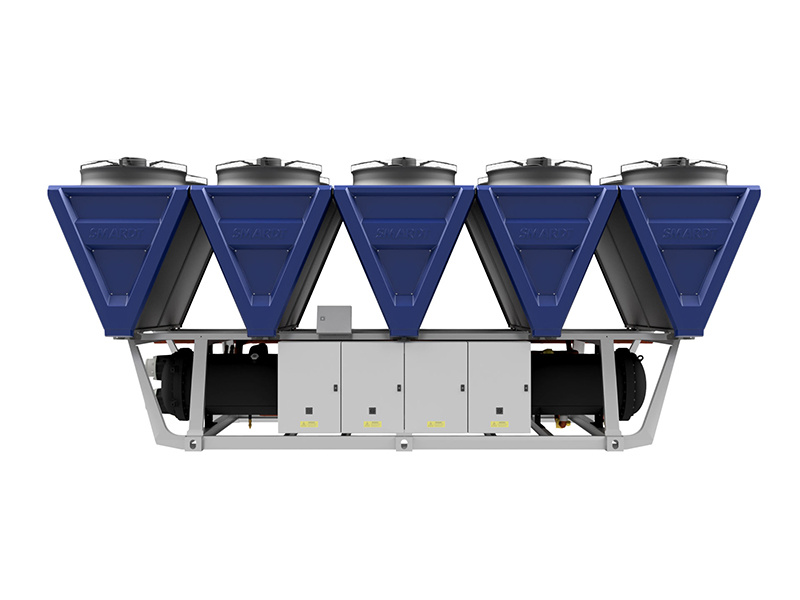

- Strong adaptability to the environment: The water-cooled cooling method is less affected by the ambient temperature, and it can maintain stable cooling performance even in high-temperature environments. Even in hot summers or harsh operating conditions, the normal operation of the equipment can be ensured.

3. Compact structure:

- Integrated design: The compressor, condenser, evaporator, water pump, water tank, and other components are integrated into one unit, with a compact structure, small footprint, and easy installation and placement. This compact design is very suitable for factories, laboratories, workshops, and other places with limited space.

- Simple piping: The internal piping is simple, reducing the length and number of bends in the pipes, reducing system resistance loss and the risk of refrigerant leakage. At the same time, the simple piping design also facilitates maintenance and repair, improving the maintainability of the equipment.

4. Precise control:

- Intelligent control system: Equipped with an advanced intelligent control system, using a PLC programmable controller or microcomputer control, it can realize full-process automatic computer adjustment control. Operators can set parameters and monitor through the human-machine interface, which is convenient and simple to operate.

- Precise temperature control: The system can precisely control the output of the cooling capacity according to the set temperature value, keeping the water temperature within a stable range to meet the high-precision requirements of temperature control in industrial production. For example, in industries with strict temperature control requirements such as electronics manufacturing and pharmaceutical production, water-cooled vortex industrial chillers can provide reliable temperature assurance.

5. Convenient installation and maintenance:

- Easy installation: Most of the assembly and commissioning work has been completed before leaving the factory. Users only need to connect the water pipes and power supply to put it into use, reducing the workload and difficulty of on-site installation. Moreover, the unit is relatively light in weight and easy to handle and install.

- Easy maintenance: The structure of the evaporator and condenser is easy to clean and maintain. For example, the shell-and-tube condenser can be cleaned inside by removing the covers on both sides, removing dirt and impurities, and maintaining good heat transfer performance.

The AquaFlow Series represents the pinnacle of efficiency and reliability in water-cooled industrial chiller technology. Engineered for continuous, heavy-duty operation, this water-cooled industrial chiller is designed to deliver precise temperature control for critical processes in manufacturing, plastic molding, and high-heat load applications. Its robust construction ensures optimal heat rejection, making it the superior choice for facilities with access to consistent cooling water. By utilizing a water-cooled condenser, this system operates with significantly higher efficiency than air-cooled counterparts, leading to substantial energy savings and a reduced carbon footprint over its lifespan.

At the heart of the AquaFlow is a high-performance, corrosion-resistant shell and tube condenser. This key component of the water-cooled industrial chiller maximizes heat transfer efficiency, allowing for a compact footprint without sacrificing capacity. The system features an intelligent microprocessor controller that provides real-time monitoring of coolant temperature, pressure, and flow rates, ensuring your process remains stable and within tight tolerances. Advanced safety controls, including high-pressure cutouts and flow switches, are integrated to protect both the chiller and your connected equipment from fault conditions.

This water-cooled industrial chiller is built for seamless integration into existing cooling loops. Its modular design simplifies maintenance, with easy access to pumps, filters, and control panels. We understand that durability is paramount; therefore, the AquaFlow utilizes industrial-grade compressors and pumps designed for 24/7 operation. Choosing our water-cooled industrial chiller means investing in a solution that guarantees process stability, lowers operational costs, and provides dependable performance for years to come, solidifying it as the backbone of your thermal management system.

Keyword:

Previous Page

Next Page

Previous Page

Next Page

More Products

Inquire Now

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!

CN

CN EN

EN