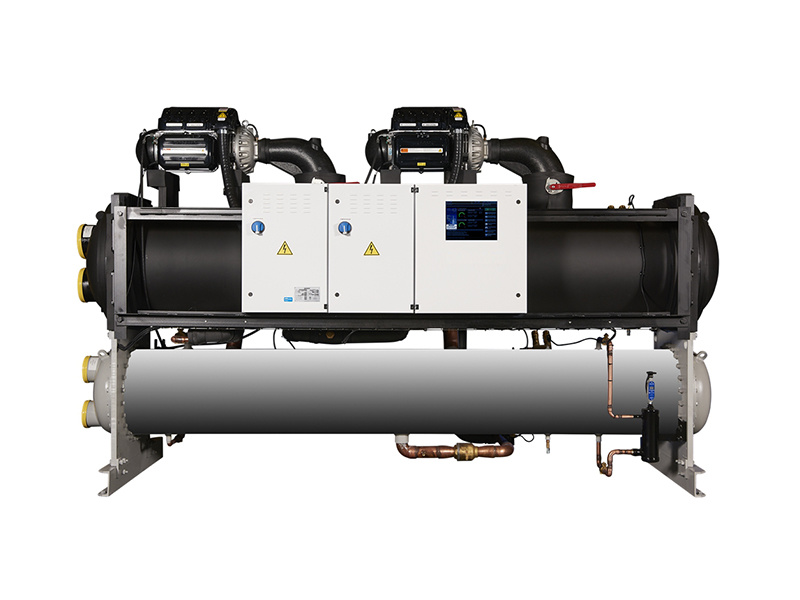

Water-cooled open industrial chiller

Equipped with high-efficiency shell and tube condensers and evaporators. The condenser can quickly transfer heat from the refrigerant to the cooling water, and the evaporator allows the refrigerant to fully evaporate and absorb heat, achieving efficient heat exchange. This structural design results in higher refrigeration efficiency for the chiller, enabling it to quickly lower the water temperature to the required level, meeting the needs of rapid cooling in industrial production.

| Cooling capacity range: 10KW to 240KW | Temperature control range: 5℃ to 30℃ |

| Temperature control accuracy: ±1℃ | Refrigerant options: R22, R10A, R407C, R134a |

| Installation environment: Indoor installation | Non-standard customization: Explosion-proof type, corrosion-resistant type |

| Optional: MODBUS RTU protocol RS485 remote communication, energy-saving frequency conversion | |

Category:

Medium temperature series

Product Attachment:

Water-cooled open industrial chillers have the following characteristics and advantages:

1. Refrigeration Performance Aspects:

- High Heat Exchange Efficiency: Equipped with high-efficiency shell-and-tube condensers and evaporators. The condenser quickly transfers heat from the refrigerant to the cooling water, and the evaporator allows the refrigerant to fully evaporate and absorb heat, achieving efficient heat exchange. This structural design results in higher refrigeration efficiency for the chiller, capable of lowering the water temperature to the required level in a short time, meeting the needs of rapid cooling in industrial production.

- Large and Stable Refrigeration Capacity: It can provide a large refrigeration capacity, meeting the cooling needs of large industrial equipment or production processes. Due to the stability of its structure and refrigeration system, the refrigeration output remains stable during long-term operation without significant fluctuations, ensuring the continuity and stability of the production process.

2. Equipment Configuration Aspects:

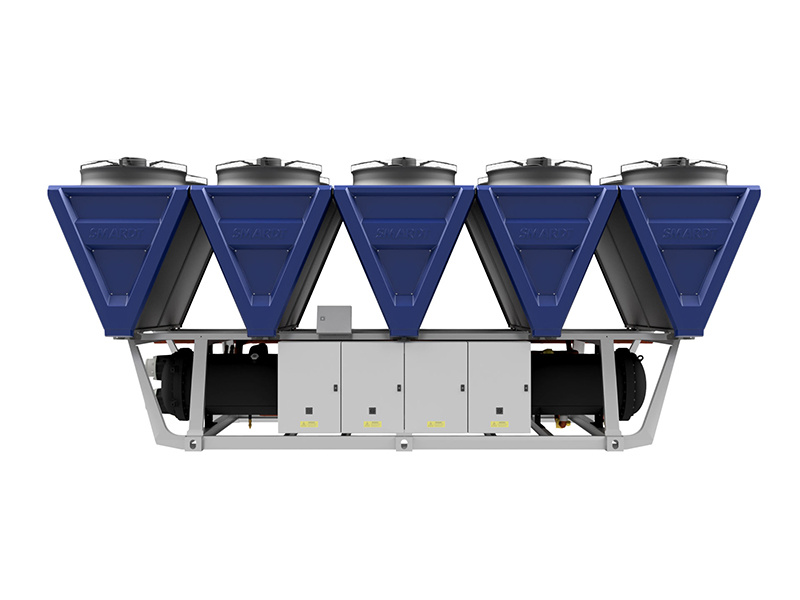

- Flexible Compressor Selection: Different types of compressors can be selected based on different refrigeration needs, such as scroll and screw types. Scroll compressors are suitable for small and medium-sized refrigeration applications, with advantages such as stable operation, low noise, and high energy efficiency; screw compressors are suitable for large-scale refrigeration systems, with characteristics of large refrigeration capacity and high reliability. Users can choose according to their actual needs, offering high flexibility.

- Free Configuration of Water Pump and Tank: It does not come with a water tank or pump; users can connect external water pumps and tanks of different specifications according to their actual needs, without being limited by the equipment's built-in components. This allows users to choose suitable water pumps and tanks based on the specific installation environment, water flow requirements, and head requirements, better meeting the needs of different industrial equipment.

3. Operation and Maintenance Aspects:

- Easy Maintenance: The open structure design makes the various components of the equipment easy to access and maintain. Maintenance personnel can easily inspect, repair, and replace key components such as compressors, condensers, and evaporators, reducing maintenance difficulty and cost. Compared with closed chillers, maintenance operations can be performed without disassembling complex outer casing structures.

- Easy Troubleshooting: When equipment malfunctions, the open structure allows maintenance personnel to quickly locate the fault point. Because all components are clearly exposed, maintenance personnel can quickly judge the cause of the fault through observation and measurement, allowing for timely repair and reducing equipment downtime.

4. Applicable Environment Aspects:

- Strong Environmental Adaptability: It has a wide range of adaptability to environmental temperature and humidity and can operate stably under different climate conditions. Even in high-temperature, high-humidity environments, through cooperation with cooling towers, heat can be effectively dissipated to ensure normal chiller refrigeration. Open chillers can also adapt well to harsh environments with more dust, requiring only regular cleaning and maintenance.

- Flexible Installation Location: Without the constraints of an outer casing, water-cooled open industrial chillers can be placed in various locations, such as inside or outside the production workshop, with lower requirements for space layout. Users can choose a suitable installation location based on the actual on-site situation.

5. Safety Protection Aspects:

- Multiple Protection Functions: It has a complete safety protection system, including high and low-pressure protection, overcurrent protection, phase loss protection, compressor overheating protection, and antifreeze protection. These protective devices monitor the equipment's operating status in real time. When abnormal conditions occur, they will immediately alarm and automatically shut down to ensure safe operation and reduce the risk of equipment failure.

- Reliable Electrical System: It uses a reliable electrical control system and high-quality electrical components, such as electrical products from brands like Schneider Electric and Siemens from Germany, ensuring stable electrical performance and reducing equipment downtime and damage caused by electrical faults.

Keyword:

Previous Page

Next Page

Previous Page

Next Page

More Products

Inquire Now

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!

CN

CN EN

EN