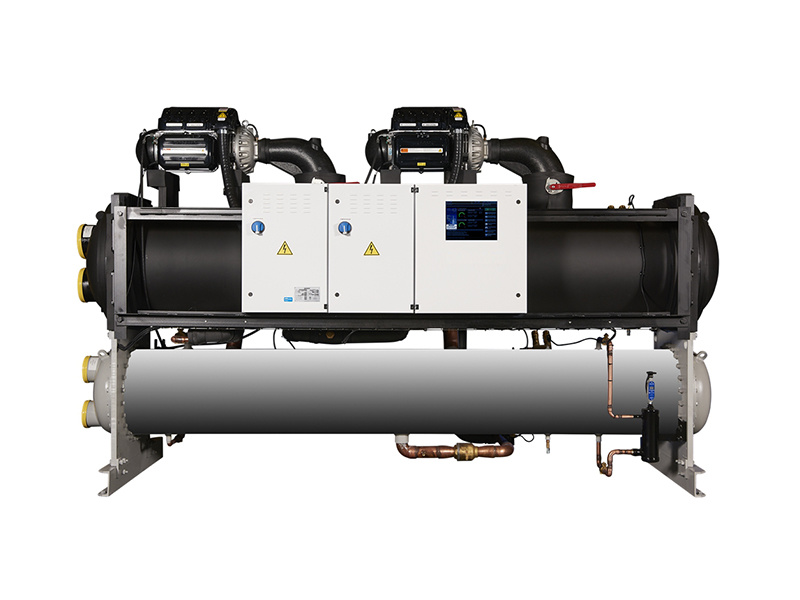

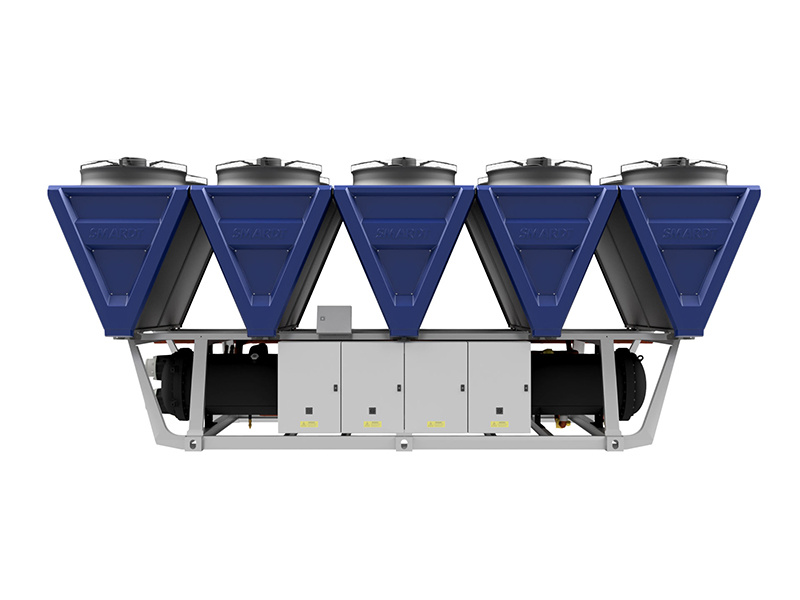

Air-cooled industrial chiller

The unit adopts a box-type structure, integrating the compressor, evaporator, condenser, water pump, water tank and other components into a single box. The layout is reasonable, space-saving, and easy to install and arrange in various industrial locations, especially suitable for workshops and laboratories with limited space.

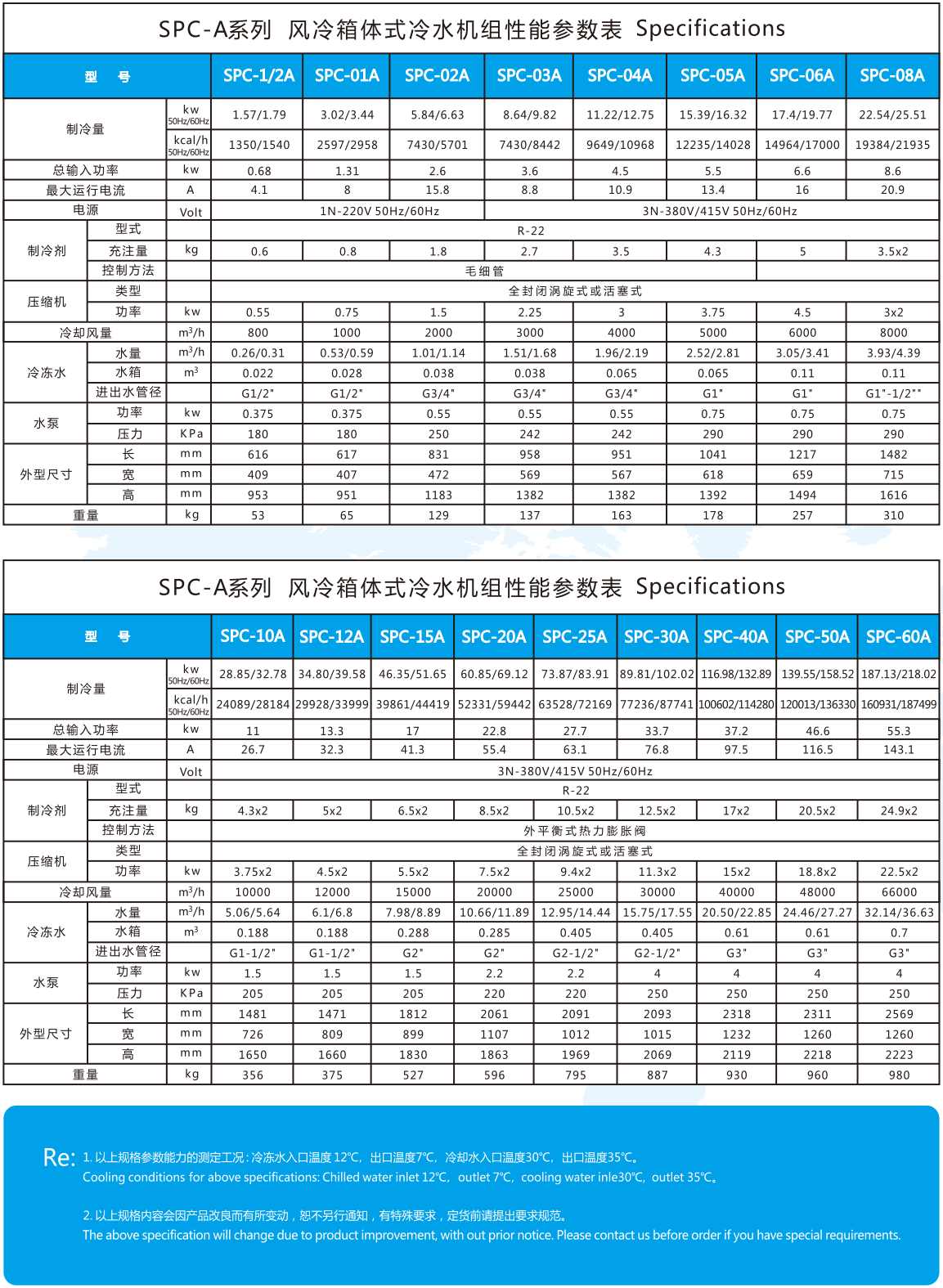

- Cooling capacity range: 2KW to 220KW

- Temperature control range: 5℃ to 30℃

- Temperature control accuracy: ±1℃

- Optional refrigerants: R22, R410A, R407C, R134a

- Installation environment: Indoor installation

- Non-standard customization: Explosion-proof, corrosion-resistant

- Optional: MODBUS RTU protocol RS485 remote communication, energy-saving frequency conversion

Category:

Medium temperature series

Product Attachment:

Air-cooled, vortex-type industrial chillers have the following features and advantages:

1. Structure and Design Aspects:

- Compact Structure: The entire unit adopts a cabinet-style structure, integrating the compressor, evaporator, condenser, water pump, water tank, and other components into a single cabinet. The layout is reasonable, occupying minimal space, making it easy to install and arrange in various industrial settings, especially suitable for workshops and laboratories with limited space.

- Aesthetic Appearance: The cabinet design results in a relatively neat and aesthetically pleasing device, matching modern industrial production environments without compromising the overall aesthetics of the workplace.

2. Refrigeration Performance Aspects:

- High-efficiency Refrigeration: Using a vortex compressor, it boasts a high energy efficiency ratio. The operating principle of the vortex compressor makes the gas compression process more continuous and stable, reducing energy loss and providing strong cooling capacity with less energy consumption, rapidly lowering water temperature to meet industrial refrigeration needs.

- Wide Range of Refrigeration Capacity: Various refrigeration capacity specifications are available to meet different industrial needs, ranging from small (several tons) to large (tens or even hundreds of tons), satisfying the cooling requirements of industrial production of various scales.

- Precise Temperature Control: Equipped with an advanced control system, it precisely controls the water temperature, maintaining it within the set range with minimal fluctuation. This is crucial for industrial processes with strict temperature control requirements, such as electronics manufacturing and pharmaceutical production.

3. Installation and Maintenance Aspects:

- Easy Installation: No complex installation is required; simply place the unit in an appropriate location and connect the power and water inlet/outlet pipes before use. Compared to water-cooled chillers, it eliminates the need for cooling towers and cooling water pumps, saving installation time and costs.

- Low Maintenance Cost: The relatively simple structure and fewer moving parts mean less daily maintenance. Moreover, the vortex compressor itself has high reliability and stability, with a long lifespan, reducing equipment maintenance and replacement costs.

4. Environmental Adaptation Aspects:

- No Water Source Required: Air cooling is used for heat dissipation; no external cooling water is required, eliminating dependence on water sources. It is suitable for areas with scarce water resources or where water is inconvenient. Even in places without cooling water supply, normal operation and continuous industrial production are ensured.

- Strong Environmental Adaptability: It has a wide range of adaptability to ambient temperature and humidity and can operate stably under various climatic conditions. In high-temperature environments, optimized heat dissipation design and a high-efficiency fan system effectively dissipate heat and maintain cooling performance.

5. Operating Characteristics Aspects:

- Quiet Operation: The vortex compressor has low vibration and noise during operation, and the cabinet's sound insulation design minimizes noise during operation, avoiding disruption of the work environment.

- Intelligent Control: It uses an intelligent control system that enables automatic start/stop, automatic refrigeration capacity adjustment, and fault alarms. It is simple and convenient to operate and improves the efficiency of equipment operation management.

- Energy-efficient and High-efficiency: During partial load operation, the vortex compressor automatically adjusts its output power according to actual needs, avoiding unnecessary energy consumption and achieving good energy-saving effects. The air-cooling heat dissipation method also eliminates the energy consumption of water pumps and other equipment in water-cooling systems.

An air cooled industrial chiller is an essential solution for precise and stable temperature control across a wide range of industrial applications. Designed for demanding production environments, this air cooled industrial chiller integrates advanced heat exchange technology, intelligent control systems, and energy-efficient components to deliver consistent cooling performance. By utilizing ambient air for heat dissipation, the air cooled industrial chiller eliminates the need for cooling towers and complex water circulation systems, making installation simpler and operation more economical. This compact yet powerful design ensures that the air cooled industrial chiller can adapt easily to different factory layouts while maintaining high operational reliability.

The robust construction of this air cooled industrial chiller ensures long service life even in harsh industrial conditions. Equipped with high-efficiency compressors, corrosion-resistant condensers, and optimized airflow channels, the air cooled industrial chiller achieves rapid heat removal and stable temperature regulation. Advanced microprocessor controls allow precise monitoring of operating parameters, enabling the air cooled industrial chiller to respond quickly to load changes and maintain optimal cooling efficiency. Safety protection functions, including overload protection, phase sequence detection, and automatic fault diagnosis, further enhance the reliability of the air cooled industrial chiller during continuous operation.

Energy efficiency is a core advantage of this air cooled industrial chiller, helping manufacturers reduce operating costs while achieving sustainable production goals. Through variable-speed fan technology and intelligent capacity control, the air cooled industrial chiller dynamically adjusts cooling output according to real-time demand. This flexible operation minimizes unnecessary power consumption and extends component lifespan. Compared with traditional water-cooled systems, the air cooled industrial chiller significantly reduces water usage, contributing to environmental protection and lowering overall maintenance expenses.

With its versatile design, this air cooled industrial chiller is widely applied in plastics processing, chemical manufacturing, pharmaceutical production, food and beverage processing, electronics cooling, and HVAC systems. The modular structure enables easy capacity expansion and convenient maintenance, allowing users to upgrade the air cooled industrial chiller system as production scales. By delivering stable cooling performance, high energy efficiency, and operational flexibility, this air cooled industrial chiller provides a reliable foundation for modern industrial processes and long-term productivity improvement.

Previous Page

Previous Page

Next Page

More Products

Inquire Now

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!

CN

CN EN

EN