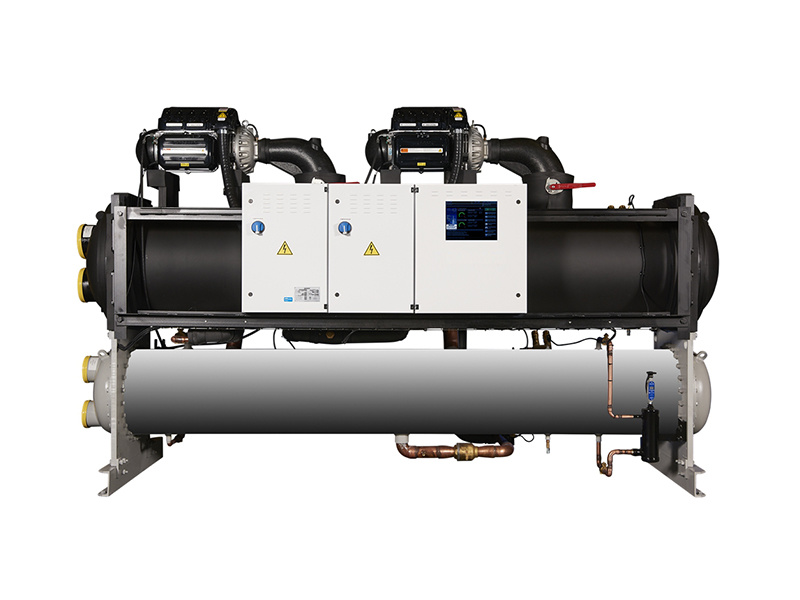

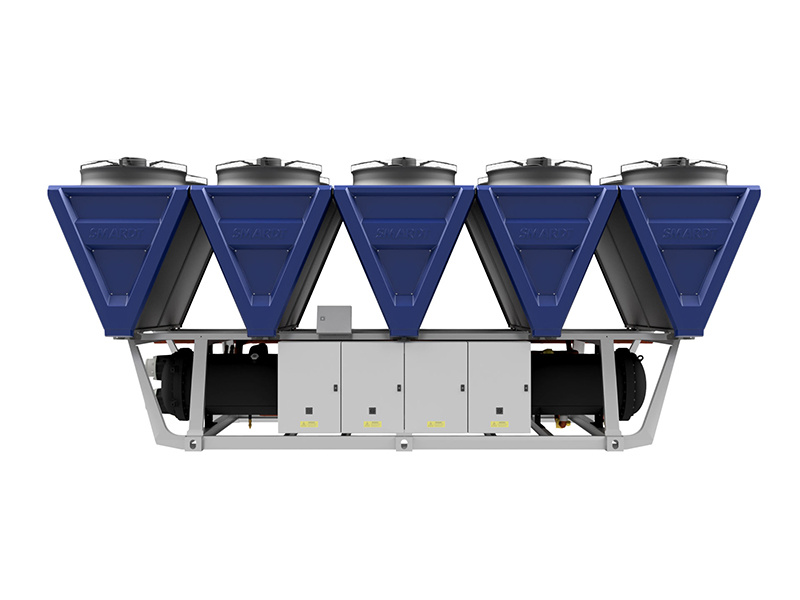

Low-medium temperature water-cooled screw chiller

High-efficiency refrigeration: Using a screw compressor, it has a high energy efficiency ratio and can provide a large amount of cooling capacity while consuming less electricity. Even under medium and low temperature conditions, it can maintain stable and efficient refrigeration capacity, quickly reducing water or medium temperature to meet the low-temperature cooling needs of industrial production.

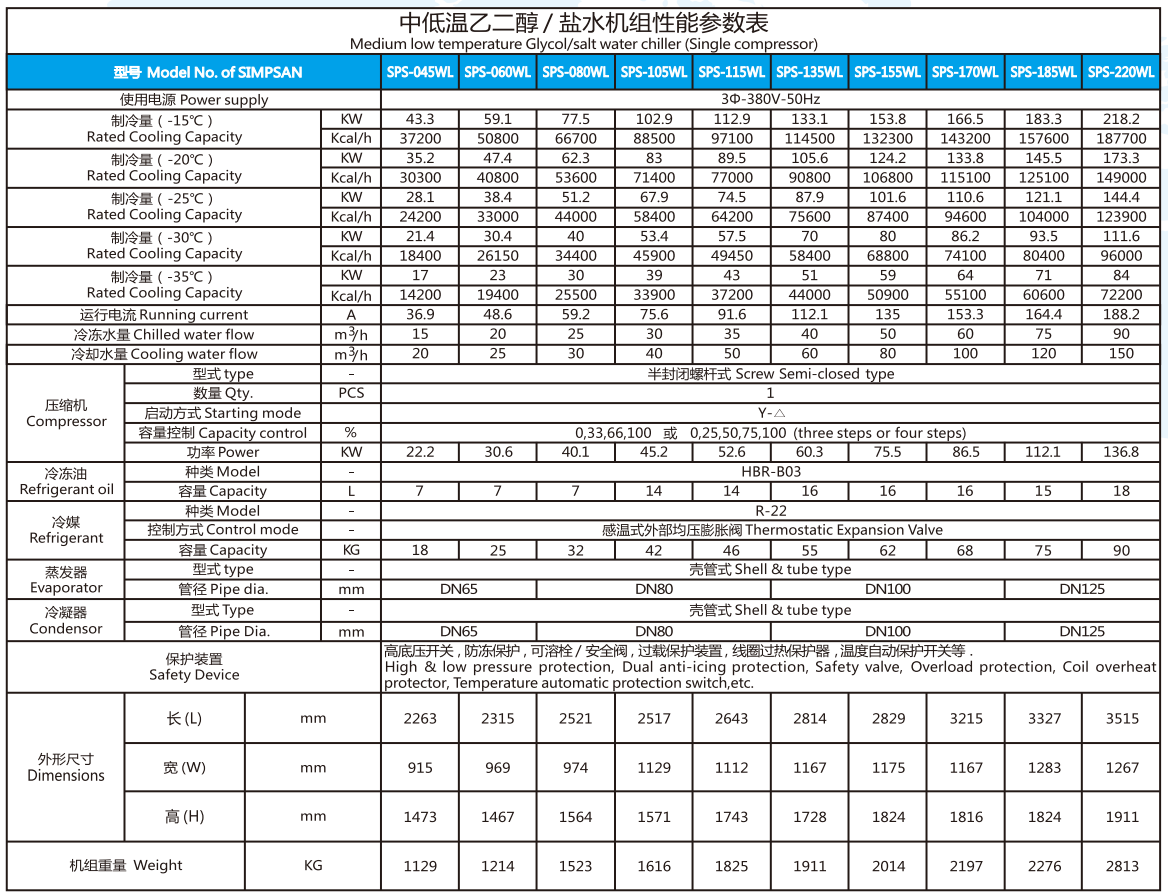

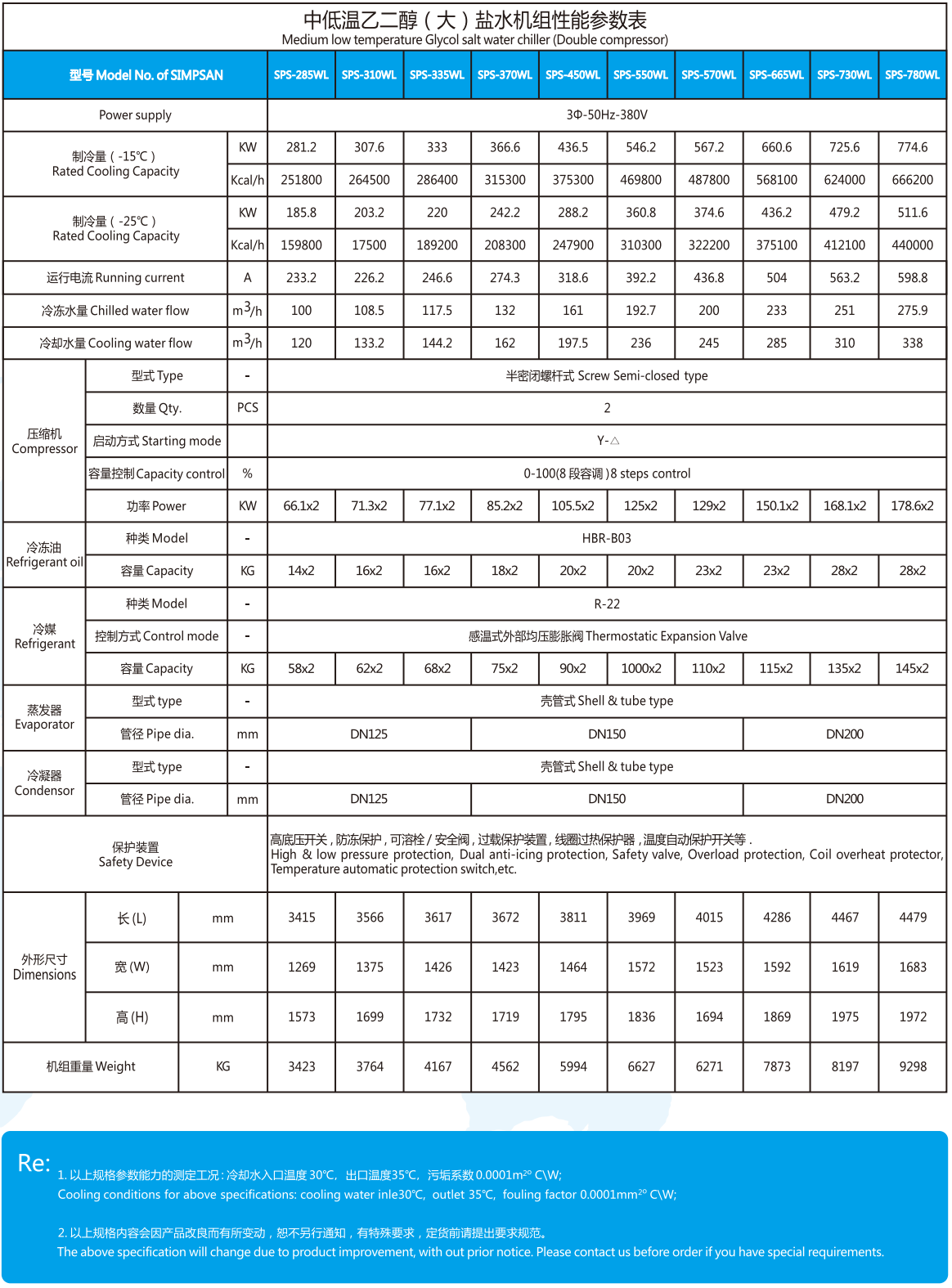

- Cooling capacity range: 50KW to 2200KW

- Temperature control range: 0℃ to -35℃

- Temperature control accuracy: ±1℃

- Optional refrigerants: R22, R407C, R404A, R507A

- Installation environment: Indoor installation

- Non-standard customization: Explosion-proof type, corrosion-resistant type

- Optional: MODBUS RTU protocol RS485 remote communication, energy-saving frequency conversion

Category:

Medium low temperature series

Product Attachment:

The main features and advantages of medium and low temperature water-cooled screw chillers are as follows:

1. Refrigeration performance aspects:

- High-efficiency refrigeration: Using screw compressors, it has a high energy efficiency ratio and can provide a large amount of cooling capacity while consuming less electricity. Under medium and low temperature conditions, it can still maintain stable and efficient refrigeration capacity, quickly reduce water temperature or medium temperature, and meet the low-temperature cooling needs of industrial production.

- Precise temperature control: Equipped with an advanced control system and high-precision temperature sensors, it can precisely control the temperature of the chilled water, keeping its fluctuation range small. This is particularly important for some industrial production processes with strict temperature control requirements, such as the chemical, pharmaceutical, and electronics industries.

- Large refrigeration capacity range: It can provide a large refrigeration capacity to meet the cooling needs of large industrial equipment or production systems. And by connecting multiple units in parallel, the output range of the refrigeration capacity can be further expanded to adapt to industrial production of different scales.

2. Structural design aspects:

- Compact structure: Key components such as condensers and evaporators use high-efficiency heat transfer tubes, and the main unit uses imported semi-hermetic twin-screw compressors. The overall structural design is compact, small in size, light in weight, and occupies less space, making it easy to install and arrange in industrial sites.

- Stable operation: Screw compressors have fewer moving parts, and there is no direct wear between the rotors, resulting in high reliability. At the same time, the vibration and noise of the unit are relatively low, the operation is stable, and it can operate stably for a long time, reducing equipment maintenance and repair costs.

3. Energy regulation aspects:

- Flexible capacity adjustment: It has a four-level or stepless capacity control system, which can automatically adjust the output power of the unit according to the changes in the actual load, operating flexibly between 25%-100%. This can not only meet the refrigeration needs under different working conditions but also avoid unnecessary energy consumption and improve energy utilization efficiency.

- High part-load efficiency: When operating at partial load, the unit can still maintain high operating efficiency, which is very beneficial for situations with large load changes in industrial production and can effectively reduce operating costs.

4. System safety aspects:

- Multiple protection functions: It has a complete safety protection system, such as compressor overheating protection, overcurrent protection, phase failure protection, high and low pressure protection, low oil level protection, etc., which can monitor the running status of the unit in real time. When an abnormal situation occurs, it will alarm and automatically shut down in time to ensure the safe operation of the equipment.

- Independent refrigeration circuit: For large-capacity units, there are usually two or more independent refrigeration circuits. Even if one circuit fails or needs maintenance, the other circuit can still operate normally, ensuring the continuity of industrial production.

5. Scope of application aspects:

- Diverse selection of coolants: Since water may freeze in the low-temperature range of -5℃~-35℃, ethylene glycol solution, brine solution, etc., need to be used as coolants. This chiller has good adaptability to different types of coolants and can select suitable coolants according to user needs and actual operating conditions.

- Wide range of applications: It can be widely used in plastics, electroplating, electronics manufacturing, pharmaceuticals, chemicals, food preservation, freezing and refrigeration, and ink printing industries, providing stable and reliable low-temperature cooling support for these industries' production processes.

6. Installation and maintenance aspects:

- Easy installation: Most of the components have been installed and debugged in the factory, and refrigerant and refrigerant oil have been added. Users only need to connect the water and electrical circuits to put them into use, reducing the workload and debugging time of on-site installation.

- Easy maintenance: The structure is relatively simple, and maintenance is relatively easy. The key components have high design and manufacturing quality, a long service life, and reduce the maintenance cost and replacement frequency of the equipment.

Keyword:

Previous Page

Previous Page

More Products

Inquire Now

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!

CN

CN EN

EN