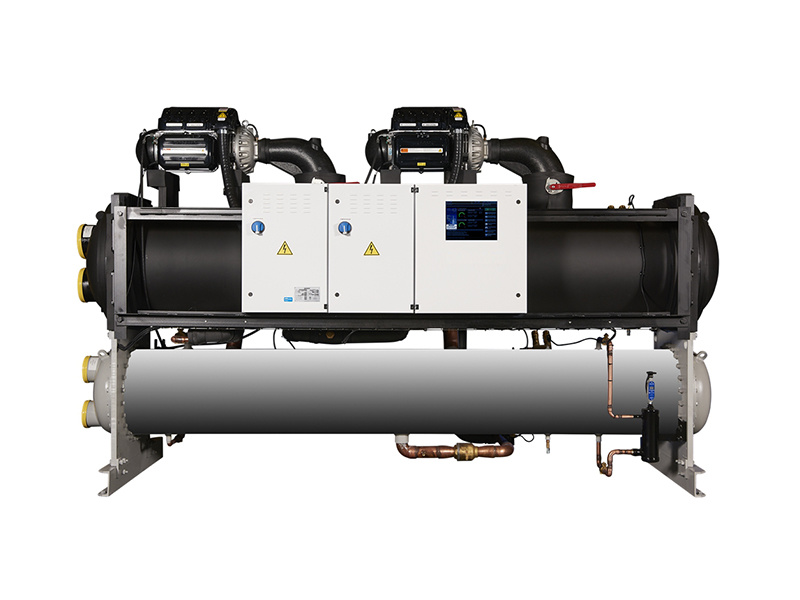

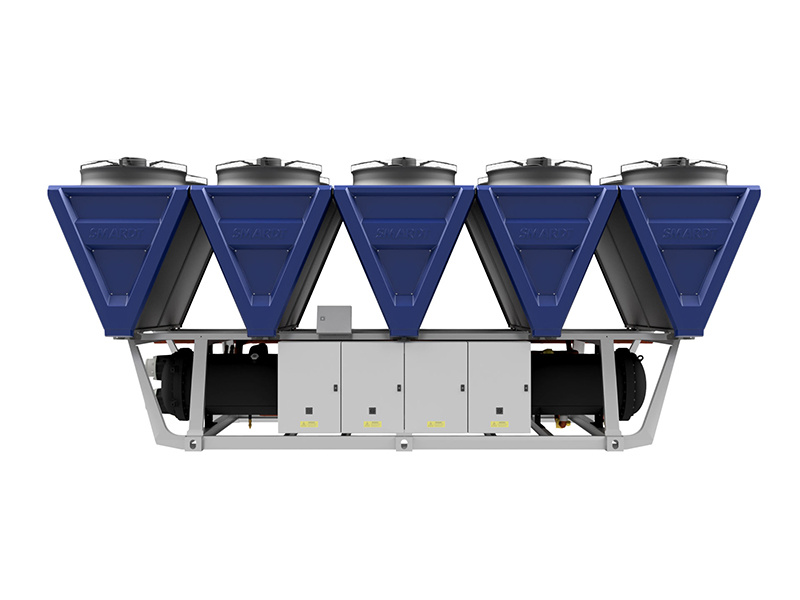

Medium and low temperature air-cooled screw chiller units

High Efficiency and Energy Saving: Utilizing a screw compressor, it boasts a high energy efficiency ratio, providing a large amount of cooling capacity while consuming less electricity. It maintains stable and efficient refrigeration capacity even under medium and low temperature conditions, quickly lowering the medium temperature to meet the low-temperature cooling needs of industrial production.

- Cooling capacity range: 60KW to 1200KW

- Temperature control range: 0℃ to -35℃

- Temperature control accuracy: ±1℃

- Refrigerant options: R22, R407C, R404A, R507A

- Installation environment: Outdoor installation

- Non-standard customization: Explosion-proof, corrosion-resistant

- Optional: MODBUS RTU protocol RS485 remote communication, energy-saving frequency conversion

Category:

Medium low temperature series

Product Attachment:

Medium and low temperature air-cooled screw chillers have the following characteristics and advantages:

1. Refrigeration Performance Aspects:

- High Efficiency and Energy Saving: Using screw compressors, it has a high energy efficiency ratio and can provide a large amount of cooling capacity while consuming less electricity. It can maintain stable and efficient refrigeration capacity under medium and low temperature conditions, quickly reduce the temperature of the medium, and meet the low-temperature cooling needs of industrial production.

- Wide Range of Refrigeration Capacity: It can provide a large refrigeration capacity output, meeting the cooling needs of large industrial equipment or production systems. By connecting multiple units in parallel, the refrigeration capacity range can be further expanded to adapt to industrial production scenarios of different scales.

- Precise Temperature Control: Equipped with an advanced control system and high-precision temperature sensors, it can precisely control the temperature of the refrigerant, keeping the fluctuation range small, which is very suitable for industrial production processes with strict temperature control requirements.

2. Structural Design Aspects:

- Compact Structure: Key components such as compressors, condensers, and evaporators are integrated in a reasonable layout, occupying less space, and easy to install and arrange in various industrial locations, especially suitable for workshops, laboratories, etc., with limited space.

- Robust and Durable: The whole machine structure is robust and can withstand certain vibrations and impacts, adapting to various complex industrial environments. Key components use high-quality materials and advanced processing technology, resulting in a long service life.

3. System Configuration Aspects:

- Complete Safety Protection: It has multiple safety protection functions, such as compressor overheat protection, overcurrent protection, high and low pressure protection, antifreeze protection, phase failure protection, reverse phase protection, etc. It can monitor the unit's operating status in real-time. In case of any abnormality, it will issue an alarm and shut down automatically to ensure the safe operation of the equipment.

- Intelligent Control System: It adopts an industrial-grade PLC centralized control system for the unit, with a user-friendly interface and menu-style prompts, allowing for arbitrary setting of the unit's operating status. It can automatically adjust the refrigeration capacity according to the actual load changes, ensuring that the unit operates at optimal efficiency and reduces operating costs.

4. Installation and Maintenance Aspects:

- Easy Installation: It does not require complex installation work. Simply place the equipment in a suitable location and connect the power supply and inlet/outlet water pipes before it can be put into use. Compared with water-cooled chillers, it does not require the installation of auxiliary equipment such as cooling towers and cooling water pumps, saving installation time and costs.

- Convenient Maintenance: The structure is relatively simple, making maintenance work relatively easy. The design of key components facilitates disassembly and replacement, reducing equipment maintenance costs and downtime. At the same time, the air-cooled heat dissipation method also reduces the maintenance workload of the water system.

5. Environmental Adaptation Aspects:

- No Water Source Required: It uses air cooling for heat dissipation and does not require external cooling water, so it is not limited by water source conditions and is suitable for areas with scarce water resources or inconvenient water use. Even in places without cooling water supply, it can operate normally to ensure the continuity of industrial production.

- Strong Adaptability: It has a wide range of adaptability to ambient temperature and humidity and can operate stably under different climatic conditions. In high-temperature environments, through optimized heat dissipation design and a high-efficiency fan system, it can effectively dissipate heat and ensure cooling effect.

Keyword:

Previous Page

Previous Page

More Products

Inquire Now

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!

CN

CN EN

EN