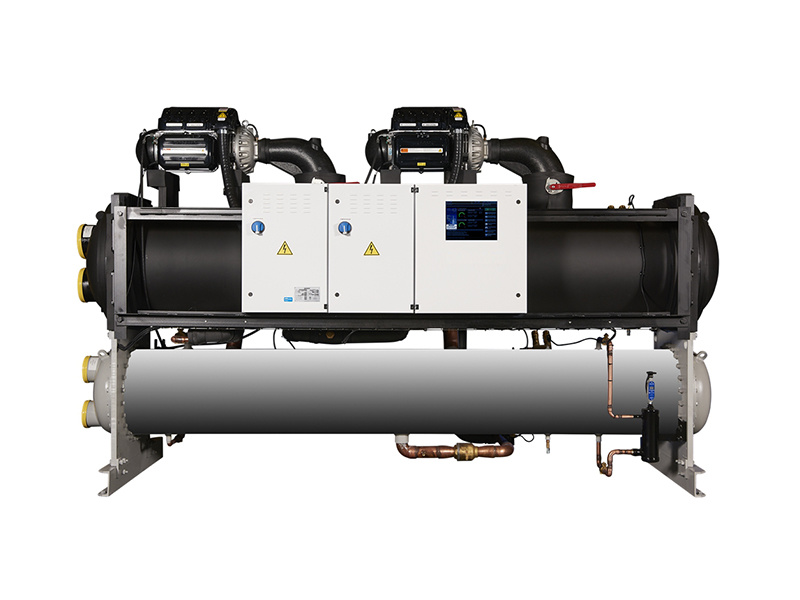

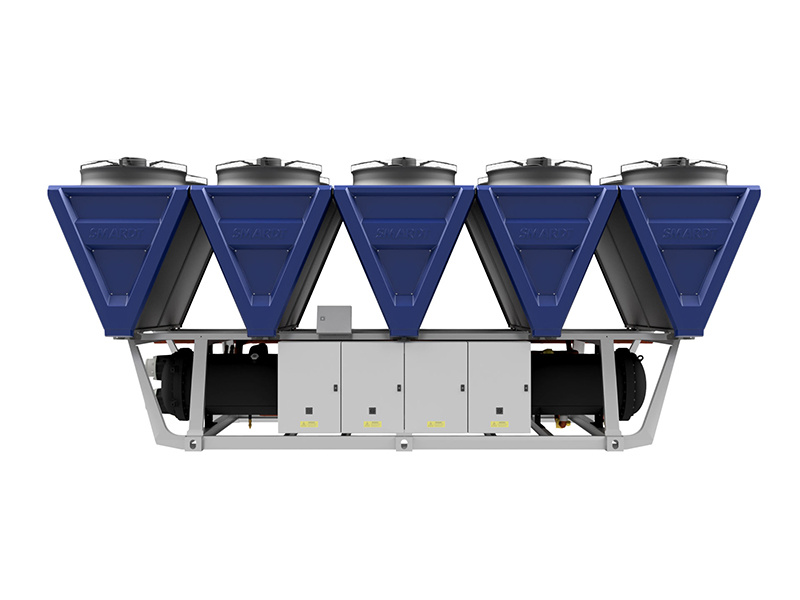

Medium and low temperature water-cooled chiller

Precise Temperature Control: Equipped with high-precision temperature sensors and an advanced control system, it can accurately control the temperature of the chilled water, with a small temperature fluctuation range. For some production processes with strict temperature control requirements, such as pharmaceutical production and chemical experiments, it ensures the stability of the production process and product quality.

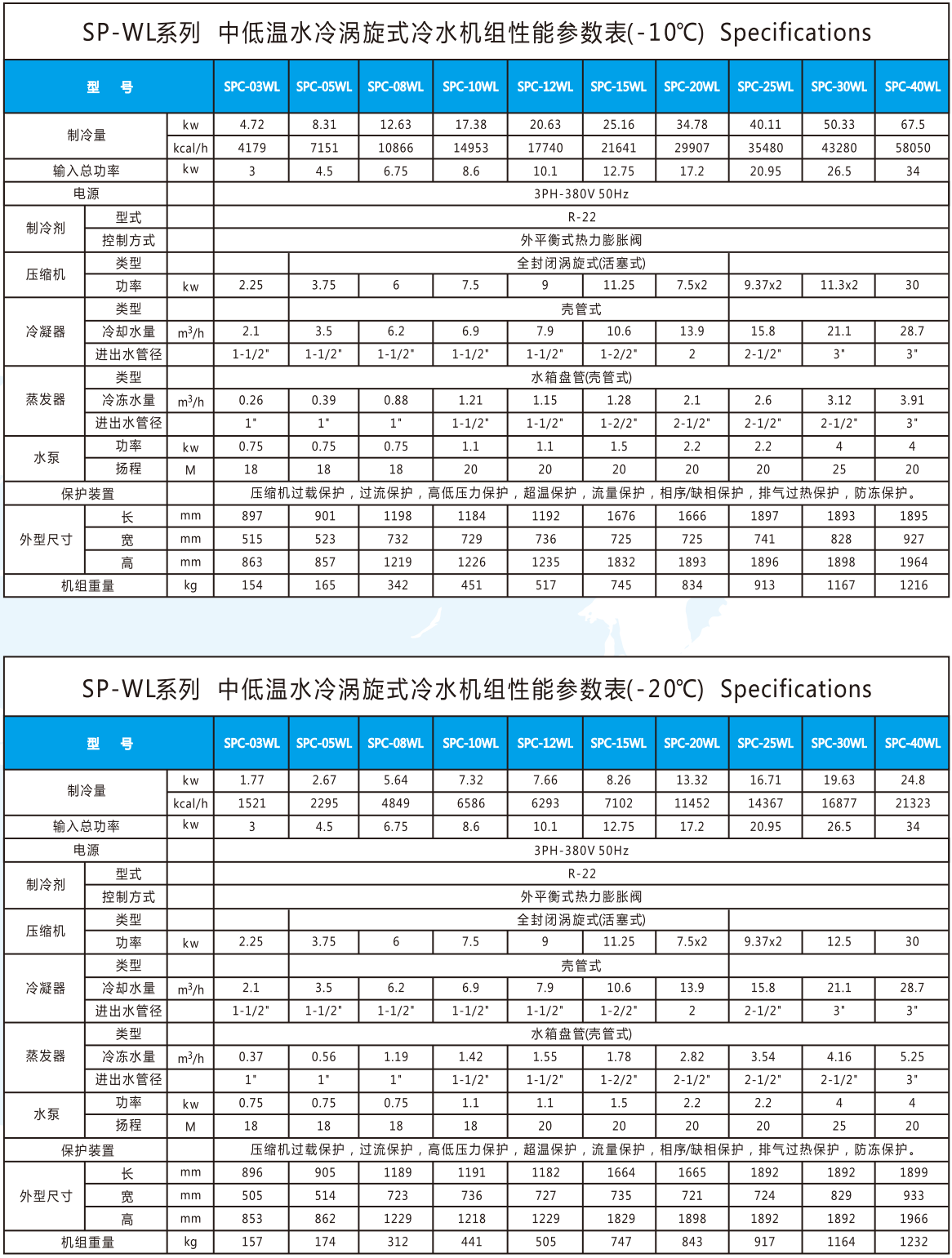

- Cooling capacity range: 10KW to 200KW

- Temperature control range: 0℃ to -35℃

- Temperature control accuracy: ±1℃

- Optional refrigerants: R22, R410A, R407C

- Installation environment: Indoor installation

- Non-standard customization: Explosion-proof type, corrosion-resistant type

- Optional accessories: MODBUS RTU protocol RS485 remote communication, energy-saving frequency conversion

Category:

Medium low temperature series

Product Attachment:

The main features and advantages of medium and low temperature water-cooled chiller units are as follows:

1. Refrigeration performance aspects:

- High-efficiency refrigeration: Maintains stable and high-efficiency refrigeration capacity under medium and low temperature conditions. Using advanced compressor technology and optimized refrigeration system design, it can quickly lower the water temperature or medium temperature to meet the low-temperature cooling needs of industrial production. For example, in the quick-freezing stage of the food processing industry, it can quickly reduce the temperature of food, ensuring food quality and taste.

- Precise temperature control: Equipped with high-precision temperature sensors and an advanced control system, it can precisely control the temperature of the chilled water, with a small temperature fluctuation range. For some production processes with strict temperature control requirements, such as pharmaceutical production and chemical experiments, it can ensure the stability of the production process and product quality.

2. Structural design aspects:

- Compact integration: Integrates key components such as compressors, evaporators, and condensers into a box-type structure, with reasonable layout and small space occupancy. This is very suitable for industrial plants, laboratories, and other places with limited space, making installation and arrangement convenient.

- Good protection: The box-type structure can provide good protection for the internal refrigeration components, reducing the impact of external environmental factors on the equipment, such as dust, moisture, and corrosive gases. It can extend the service life of the equipment and reduce maintenance costs.

3. System configuration aspects:

- Safe and reliable: It has multiple safety protection functions, such as compressor overheat protection, overcurrent protection, high and low pressure protection, and antifreeze protection. When the equipment encounters abnormal situations, it can alarm and automatically shut down in time to ensure the safe operation of the equipment and reduce production interruptions and equipment damage caused by failures.

- Intelligent control: It adopts an intelligent control system with a user-friendly interface that is easy to operate and monitor. It can realize remote control and automated operation, making it convenient for users to manage and adjust the equipment and improve production efficiency.

4. Heat exchange efficiency aspects:

- High-efficiency heat exchange components: Shell and tube condensers and evaporators are usually used, which have the advantages of simple structure, high heat exchange efficiency, less cold loss, and easy oil return. It can quickly and effectively exchange heat, improve energy utilization rate, and reduce operating costs.

- Good cooling effect: Water-cooled cooling method, using water as the cooling medium, has a high specific heat capacity and thermal conductivity, which can quickly remove heat and ensure the efficient operation of the refrigeration system. Moreover, the water temperature is relatively stable and is not affected by the ambient temperature, making the refrigeration effect of the chiller more stable and reliable.

5. Operation and maintenance aspects:

- Stable operation: The overall structure is strong, the vibration and noise during operation are small, and the matching accuracy between the components is high, which can ensure the long-term stable operation of the equipment. It reduces downtime and maintenance costs caused by equipment failures.

- Easy maintenance: The box-type structure makes the maintenance and inspection of the equipment more convenient. Operators can easily open the cabinet to check, replace, and repair components. At the same time, the standardized design and universal components of the equipment are also conducive to later maintenance.

Keyword:

More Products

Inquire Now

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!

CN

CN EN

EN