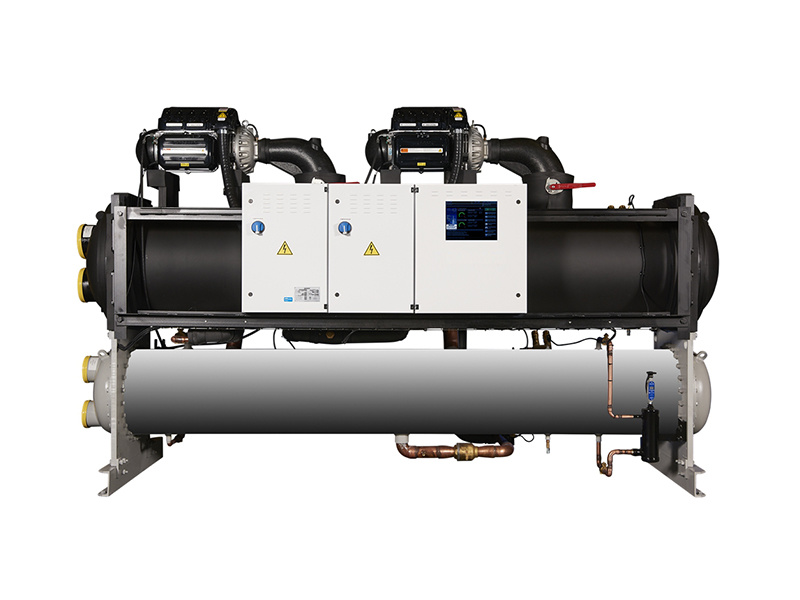

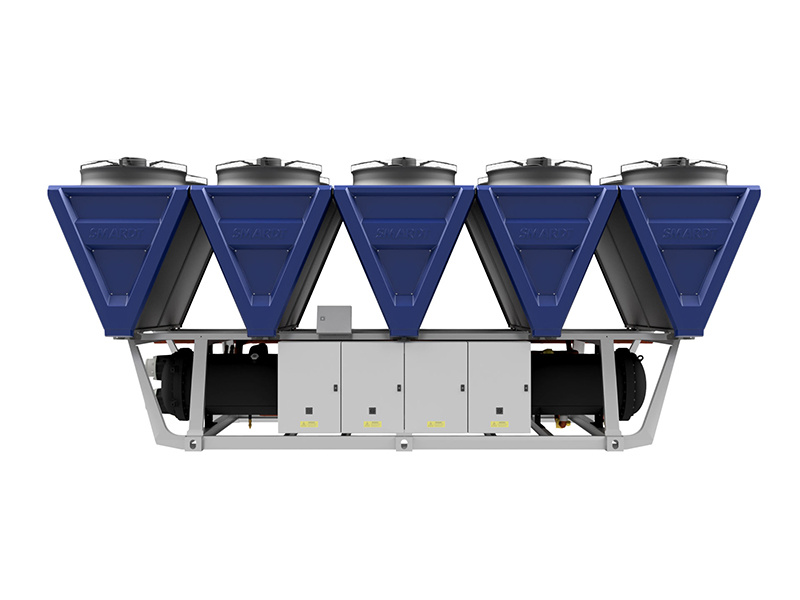

Explosion-proof chiller unit

All components are manufactured in accordance with national explosion-proof standards. For example, electrical equipment conforms to GB3836 series standards, and key components such as compressors, fans, water pumps, and electrical control boxes have special explosion-proof markings, such as ExdIIBT4 and ExdIICT4, which can prevent explosions caused by electrical sparks, high temperatures, etc., in flammable and explosive environments, ensuring the safety of personnel and equipment.

Category:

Special Customized Series

Product Attachment:

Explosion-proof chillers have the following characteristics and advantages:

Characteristics:

Strict explosion-proof design:

- Compliant with explosion-proof standards: All components are manufactured according to national explosion-proof standards. For example, electrical equipment complies with GB3836 series standards, and key components such as compressors, fans, water pumps, and control boxes have special explosion-proof markings, such as ExdIIBT4 and ExdIICT4, etc., which can prevent explosions caused by electrical sparks, high temperatures, etc., in flammable and explosive environments, ensuring the safety of personnel and equipment.

- Special structural design: For example, the explosion-proof electrical box shell is made of welded steel plate, which is high in strength and durable, and can effectively withstand the explosion impact that may occur inside, preventing the explosion from spreading to the external environment; it uses a special sealing structure to prevent flammable and explosive gases from entering the equipment.

“Ex” indicates explosion-proof; “d” indicates flameproof type, which means that the parts of the equipment that may generate sparks, arcs, and dangerous temperatures are enclosed in a shell. When an internal explosion occurs, the shell can withstand the explosion pressure without damage and prevent the explosion flame from spreading outwards.

“IIC” indicates that it is suitable for Class C hazardous areas in Class I explosive gas environments except for coal mines. In Class I explosive gas environments, IIC is the highest explosion-proof level and can be used in the most dangerous gas environments such as hydrogen, acetylene, and carbon disulfide.

“T4” indicates that the maximum surface temperature of the equipment does not exceed 135℃. Temperature classes are divided into six levels from T1 to T6. The lower the temperature, the higher the level, and the better the explosion-proof performance.

The main characteristics and advantages of equipment with ExdIICT4 explosion-proof rating are:

1. Strict explosion-proof structural design:

Robust shell: The shell is made of high-strength metal materials, which can withstand the pressure generated by internal explosions and prevent the explosion from spreading to the surrounding environment.

Good sealing performance: It has a good sealing structure to prevent explosive gases from entering the equipment, and also prevents sparks and high temperatures inside the equipment from leaking to the outside.

2. Professional electrical system design:

Explosion-proof electrical components: Explosion-proof electrical components are selected, such as explosion-proof motors, explosion-proof switches, and explosion-proof sensors, to ensure the safe operation of the electrical system in hazardous environments.

Wiring protection: Special protection is provided for electrical wiring, such as using explosion-proof cables and explosion-proof junction boxes, to prevent short circuits, leakage, etc., from causing explosions.

Precise temperature control: Equipped with an intelligent control system, it can automatically adjust the cooling capacity according to load changes, accurately control the water temperature, and control temperature fluctuations within a small range to meet the precise temperature requirements of different processes.

3. Reliable operating performance:

High-quality components: High-quality compressors, heat exchangers, controllers, and other components are selected to ensure the overall performance and reliability of the unit. For example, the compressor has few running parts, low vibration, and low failure rate, and can run stably for a long time.

Multiple protection functions: It has protection functions such as power phase sequence, phase loss, high and low voltage, insufficient water flow, antifreeze for chilled water, compressor and motor overload, and compressor overheating, to ensure the safe operation of the unit under various operating conditions.

Advantages:

1. High safety:

Suitable for the most dangerous gas environments: Because it has an IIC explosion-proof rating, it can operate safely in environments containing highly flammable and explosive gases such as hydrogen and acetylene, providing extremely high safety protection for personnel and equipment.

Reliable explosion-proof performance: It has undergone rigorous testing and certification to ensure that it can effectively prevent explosions and reduce accident risks under various hazardous conditions.

2. Wide range of applications:

Suitable for various industries: In the petroleum, chemical, natural gas, and pharmaceutical industries, there are many places where flammable and explosive gases exist. Equipment with ExdIICT4 explosion-proof rating can meet the special needs of these industries.

Adaptable to different environmental conditions: Whether indoors or outdoors, high or low temperatures, humid or dry environments, it can maintain stable explosion-proof performance and ensure the safe operation of the equipment.

3. Good performance and reliability:

High-performance equipment components: Using high-quality materials and advanced manufacturing processes to ensure that the equipment is stable and reliable in performance and can run continuously for a long time.

Energy-efficient and efficient: Using a high-efficiency refrigeration system and advanced compressor technology, it can maintain a high energy efficiency ratio even under partial load, which can effectively reduce operating energy consumption and save operating costs.

Flexible installation: There are various installation methods, and indoor or outdoor installation can be selected according to the actual site conditions. It can be used alone or in multiple modules in parallel, making it easy for users to expand and adjust according to cooling needs.

Easy maintenance: The overall structure is reasonably designed, and the open structure facilitates daily maintenance and inspection, reducing downtime and maintenance costs caused by equipment failures.

Keyword:

Previous Page

Next Page

Previous Page

Next Page

More Products

Inquire Now

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!

CN

CN EN

EN