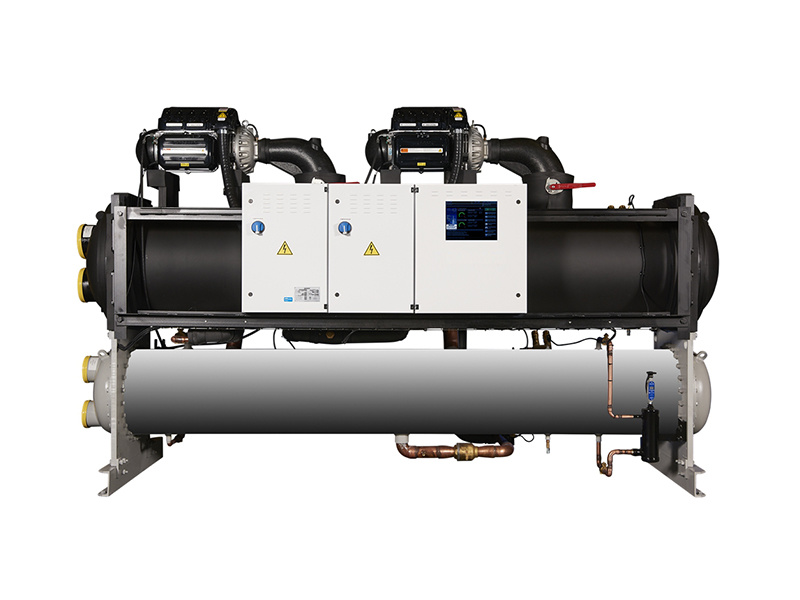

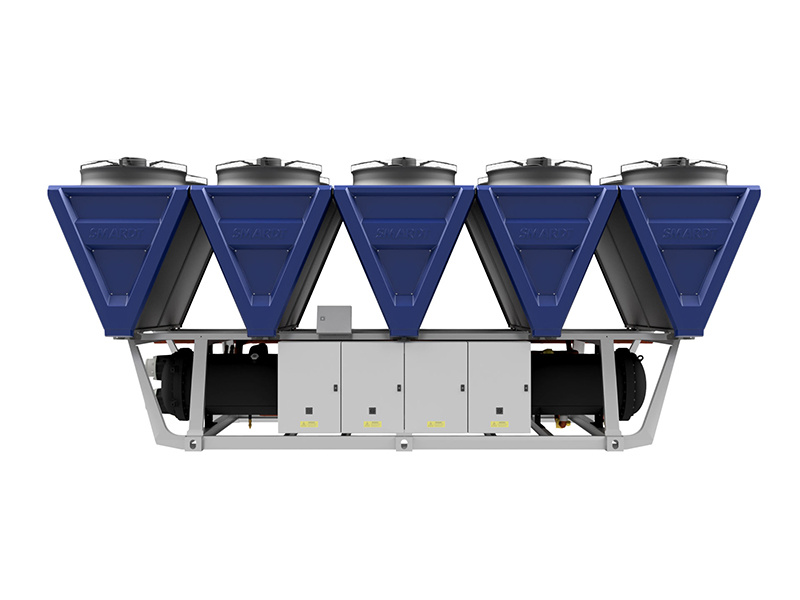

Corrosion-resistant chiller

Corrosion-resistant materials are used: Key components such as evaporators, condensers, and pipelines that come into contact with refrigerants or water are made of corrosion-resistant materials such as 316 stainless steel and titanium alloys. These materials have good resistance to corrosive media such as acids, alkalis, and salts, and can operate stably for a long time in harsh chemical environments. For example, in the electroplating industry, various corrosive solutions are often present, and the use of corrosion-resistant chillers ensures the normal operation of the equipment.

Category:

Special Customized Series

Product Attachment:

The main features and advantages of corrosion-resistant chillers are as follows:

1. Material Selection Aspects:

- Use of corrosion-resistant materials: Key components such as evaporators, condensers, and pipelines that come into contact with refrigerants or water will use corrosion-resistant materials such as 316 stainless steel and titanium alloys. These materials have good resistance to corrosive media such as acids, alkalis, and salts, and can operate stably for a long time in harsh chemical environments. For example, in the electroplating industry, there are often various corrosive solutions, and the use of corrosion-resistant chillers can ensure the normal operation of the equipment.

- Special coating treatment: Some components may undergo special coating treatments, such as anti-corrosion paint and nano-coatings, to further enhance their corrosion resistance. This coating can effectively prevent corrosive substances from eroding the metal surface, extending the service life of the equipment.

2. Structural Design Features:

- Compact sealed structure: It has a compact structural design, reducing the gaps inside the equipment and exposed interfaces, reducing the risk of corrosive media entering the equipment. At the same time, good sealing performance can prevent external corrosive gases and liquids from entering the unit, protecting internal electrical components and mechanical parts35.

- Easy maintenance and cleaning: Considering the need for corrosion protection, the structural design is usually convenient for daily maintenance and cleaning. For example, the evaporator and condenser are designed for easy disassembly and installation, allowing users to regularly clean them to remove surface dirt and corrosive substances, maintaining the good performance of the equipment.

3. Performance Advantages:

- High-efficiency refrigeration performance: Equipped with high-efficiency compressors and heat exchangers, it can quickly and effectively lower the water temperature to meet user needs for refrigeration capacity and speed. Even in corrosive environments, it can maintain stable refrigeration performance to ensure the smooth progress of the production process.

- Precise temperature control: Using an advanced temperature control system, it can precisely control the temperature of the cold water with a small fluctuation range. This is very important for some production processes with strict temperature requirements, such as electronics manufacturing and pharmaceutical production, and can ensure product quality and stability.

- Good energy-saving effect: Through optimized system design and advanced control technology, corrosion-resistant chillers have good energy-saving effects, reducing energy consumption and operating costs. For example, using an intelligent control system to automatically adjust the refrigeration capacity according to the actual load avoids energy waste.

4. Safety and Reliability:

- Multiple safety protections: It has multiple safety protection devices, such as compressor overload protection, high and low pressure protection, insufficient water flow protection, and temperature sensor failure protection, to ensure the safe and reliable operation of the unit. When an abnormal situation occurs, the equipment can automatically shut down in time to prevent the expansion of faults and protect the safety of equipment and personnel.

- Stable operating performance: After rigorous testing and verification, corrosion-resistant chillers can maintain stable operating performance under various harsh environmental conditions, reducing downtime and maintenance caused by equipment failures, and improving production efficiency.

- Wide applicability: It can be applied to various scenarios with corrosive environments, such as the chemical, electroplating, pharmaceutical, electronics, and food processing industries25. In these industries, various corrosive substances are produced during the production process, and ordinary chillers are easily corroded and damaged, while corrosion-resistant chillers can adapt well to this environment and provide reliable cooling protection for the production process.

Keyword:

Previous Page

Next Page

Previous Page

Next Page

More Products

Inquire Now

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!

CN

CN EN

EN