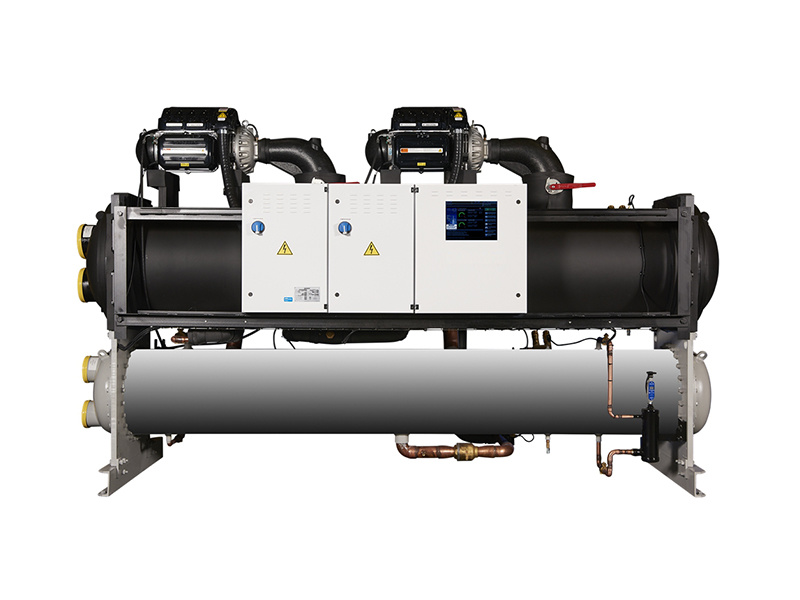

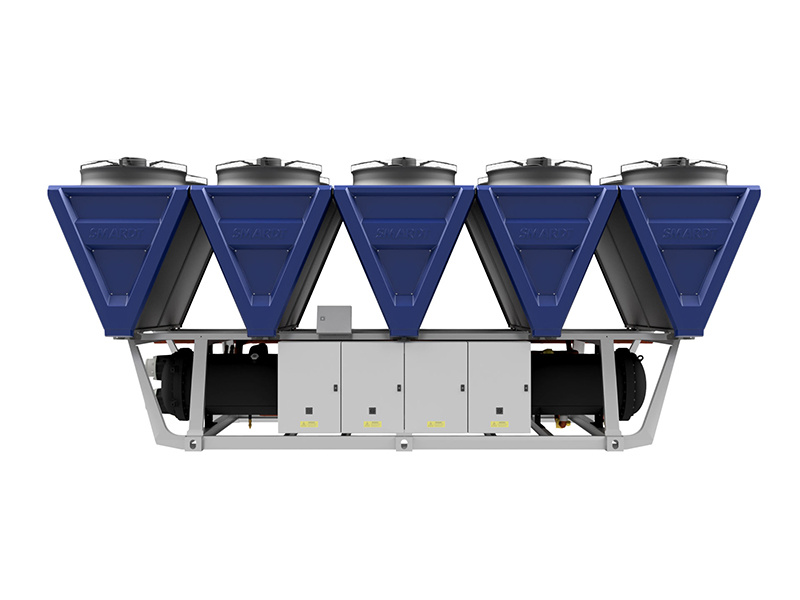

System integrated chiller

Compact Structure: The main components of the refrigeration system, such as the compressor, condenser, evaporator, throttling device, water pump, water tank, and control system, are highly integrated into a single frame or chassis. This integrated design reduces the equipment's footprint, making it better suited for installation needs in large buildings, factories, or project sites with limited space.

Category:

Special Customized Series

Product Attachment:

Integrated, self-contained chillers have the following characteristics and advantages:

1. High degree of integration:

- Compact structure: The main components of the refrigeration system, such as the compressor, condenser, evaporator, throttling device, water pump, water tank, and control system, are highly integrated into a single frame or cabinet. This integrated design reduces the floor space occupied by the equipment, making it better suited to the installation needs of large buildings, factories, or project sites with limited space.

- Optimized piping: Internal piping connections are prefabricated in the factory, resulting in a more rational and compact layout. This reduces on-site piping connection work and potential leakage risks, improving system sealing and reliability.

2. Convenient installation and commissioning:

- Factory pre-commissioning: Assembly, commissioning, and testing of the unit have been completed in the factory to ensure that the performance of each component and the overall operation of the system meet the requirements. On-site, users only need to connect the water and electrical circuits for immediate use, significantly shortening on-site installation and commissioning time, reducing project construction cycles and labor costs.

- Simple operation: Equipped with an intelligent control system and a user-friendly interface, users only need simple training to master the operation of the unit, eliminating the need for professional technicians to perform complex debugging and operation.

3. High operating efficiency:

- Optimized system matching: Each component is optimized and matched during the design and integration process to achieve better collaborative work and improve the overall operating efficiency of the refrigeration system. For example, the selection of the compressor is matched with the heat exchange capacity of the condenser and evaporator to fully utilize the compressor's performance, increasing refrigeration capacity and energy efficiency ratio.

- Precise energy regulation: It has a precise energy regulation function that can automatically adjust the refrigeration capacity according to the actual load demand, avoiding energy waste. Some large chillers also use advanced variable frequency technology to adjust the compressor speed in real-time according to load changes, further improving energy utilization efficiency.

4. Convenient maintenance:

- Centralized layout for easy maintenance: Since all components are integrated, maintenance personnel can easily inspect and maintain the entire unit without having to travel between different equipment, improving maintenance efficiency. The centralized layout also facilitates unified management and monitoring of the equipment.

- Intelligent fault diagnosis: Equipped with an intelligent fault diagnosis system that can monitor the operating status of the unit in real-time. When a fault occurs, it immediately issues an alarm signal and displays the fault code, allowing maintenance personnel to quickly and accurately locate the fault point and shorten the troubleshooting time.

5. High reliability:

- Strict quality control: Production and assembly are carried out in the factory, allowing for strict control of the quality of each link to ensure the overall quality and stable performance of the unit. It has also undergone rigorous testing and inspection to ensure reliable operation under various operating conditions.

- Multiple protection functions: Multiple protection devices are installed, such as compressor overload protection, high and low pressure protection, insufficient water flow protection, and temperature sensor fault protection, to ensure the safe and reliable operation of the unit and reduce downtime and repair time due to faults.

6. Wide adaptability:

- Good environmental adaptability: It can adapt to different environmental conditions, such as high temperatures, low temperatures, and high humidity. The design also incorporates protective measures such as waterproofing, dustproofing, and corrosion protection to improve the unit's environmental adaptability and service life.

- Diverse application areas: It can be widely used in large shopping malls, office buildings, hospitals, factories, data centers, and many other large venues to meet the refrigeration needs of different types of buildings and projects.

7. Energy saving and environmental protection:

- Energy-saving design: Through optimized system design and the application of advanced technologies, the unit's energy consumption is reduced, saving operating costs. For example, the use of high-efficiency heat exchangers and optimized refrigerant circulation systems improves energy utilization efficiency.

- Environmentally friendly refrigerants: Environmentally friendly refrigerants can be selected to reduce the impact on the environment, complying with current environmental policies and sustainable development requirements.

An integrated chiller system represents the pinnacle of efficiency and streamlined thermal management for industrial and commercial applications. Unlike traditional modular setups with disparate components, this unified solution combines the chiller, pumps, hydronic piping, cooling towers (if applicable), and advanced controls into a single, pre-engineered package. This holistic approach eliminates compatibility concerns and significantly reduces the complexity of installation and commissioning. The primary advantage of such an integrated system is its optimized performance, as all sub-components are designed from the outset to work in perfect harmony, maximizing energy efficiency and reliability.

The core intelligence of our integrated chiller system lies in its sophisticated control architecture. A central, user-friendly interface provides real-time monitoring, precise temperature control, and automated sequencing of all operational phases. Smart algorithms continuously adjust pump speeds, compressor staging, and fan operation in response to dynamic cooling loads. This proactive management not only ensures exceptional process stability but also delivers substantial energy savings by preventing the wasteful operation common in poorly coordinated standalone systems. Furthermore, integrated diagnostics and remote connectivity facilitate predictive maintenance, minimizing unexpected downtime.

From data centers and pharmaceutical manufacturing to plastic processing and HVAC support, the versatility of a well-designed integrated chiller system is immense. By consolidating all critical cooling components into one footprint, it saves valuable floor space and simplifies facility layout. Every unit undergoes rigorous factory testing as a complete system, guaranteeing performance before it arrives on-site. Choosing our integrated chiller solution means investing in lower lifecycle costs, enhanced operational simplicity, and a future-proof foundation for your critical cooling needs, ensuring precise thermal control for years to come.

Keyword:

Previous Page

Next Page

Previous Page

Next Page

More Products

Inquire Now

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!

CN

CN EN

EN