Mobile containerized chiller room

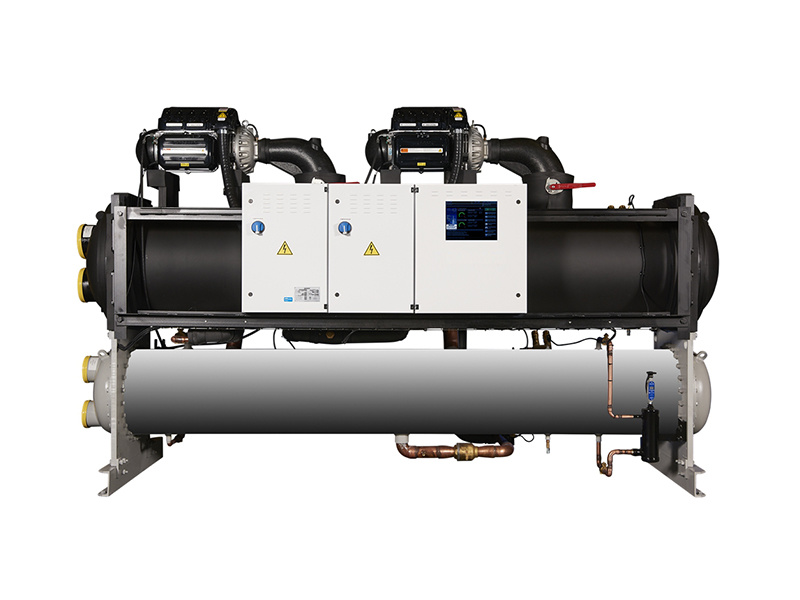

Equipment Integration: The main equipment and components required for the refrigeration system, including chillers, pumps, water tanks, water treatment equipment, valves, pipes, and control systems, are integrated into a single container to form a complete, independent refrigeration system. This high degree of integration reduces the amount of on-site installation and commissioning work, improving the system's reliability and stability.

Category:

Special Customized Series

Product Attachment:

Mobile containerized chiller rooms have the following characteristics and advantages:

1. High integration:

- Equipment integration: The main equipment and components required for the refrigeration system, such as chillers, pumps, water tanks, water treatment equipment, valves, pipes, and control systems, are integrated into a container to form a complete and independent refrigeration system. This high degree of integration reduces the workload of on-site installation and commissioning, improving the reliability and stability of the system.

- Functional integration: It not only has refrigeration functions but may also integrate monitoring, alarm, and remote control functions, allowing users to monitor and manage the chiller room's operating status in real-time.

2. Mobility:

- Flexible transportation: The container format allows the chiller room to be easily transported by trucks, ships, trains, and other transportation tools, enabling rapid deployment to different locations. This is suitable for temporary or mobile refrigeration needs, such as construction sites, field operations, and temporary event venues.

- Reusability: After completion of a project, it can be moved to other locations for continued use, improving equipment utilization and reducing investment costs.

3. Rapid deployment:

- Simple on-site preparation: Upon arrival at the site, only simple basic fixing, water and electricity connection work is needed before it can be put into use, greatly shortening the project construction cycle. Compared to traditional fixed chiller rooms, it reduces on-site construction time and complexity.

- Fast emergency response: In emergencies, such as temporary rescue after natural disasters or emergency cooling for unexpected events, mobile containerized chiller rooms can quickly provide refrigeration services to meet urgent needs.

4. Small footprint:

- High space utilization: The dimensions of the container are relatively standardized, and the internal equipment layout is compact, making full use of limited space. This is suitable for use in places with limited space, such as construction sites in city centers and narrow factory areas.

- No special building required: It does not require the construction of a separate machine room building, saving land resources and construction costs, and avoiding time delays caused by building approvals.

5. Good protection:

- Robust structure: The container itself has a sturdy steel frame that can withstand a certain amount of external impact and harsh environmental conditions, such as wind, rain, and vibration, protecting the safety of the internal equipment.

- Strong environmental adaptability: It has good sealing and insulation performance, effectively preventing dust, moisture, and heat from affecting the equipment, ensuring normal operation in various environments.

6. Easy maintenance:

- Centralized maintenance: The equipment is concentrated in one container, facilitating centralized inspection, repair, and maintenance by personnel, improving maintenance efficiency.

- Customizable maintenance windows: Specialized maintenance windows or inspection doors can be set on the container according to user needs, facilitating maintenance personnel operations without affecting the normal operation of the equipment.

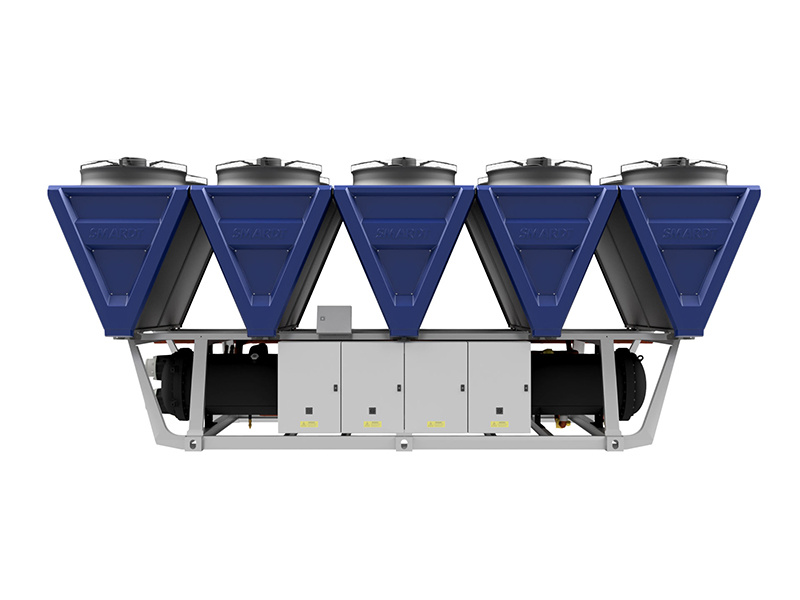

Our Mobile Container Chiller Unit is designed to deliver reliable and efficient cooling for various industrial and commercial applications. This portable solution is perfect for temporary cooling needs, events, or locations where permanent systems are unavailable. The Mobile Container Chiller Unit features a robust design with advanced temperature control, ensuring optimal performance in demanding environments. Whether you need cooling for construction sites, data centers, or emergency situations, this unit provides quick deployment and consistent results.

Equipped with high-efficiency compressors and user-friendly controls, the Mobile Container Chiller Unit offers easy operation and low maintenance. Its compact, containerized design allows for seamless transportation and setup, making it ideal for on-the-go cooling requirements. The unit is built to withstand harsh conditions, with durable materials and corrosion-resistant components. With customizable cooling capacities, our Mobile Container Chiller Unit can be tailored to meet your specific needs.

Choose our Mobile Container Chiller Unit for a flexible, cost-effective cooling solution. Its energy-efficient operation reduces power consumption while delivering powerful performance. Trust in our cutting-edge technology to keep your operations running smoothly, no matter where you are.

Keyword:

Previous Page

Previous Page

Next Page

More Products

Inquire Now

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!

CN

CN EN

EN