In the global industrial temperature control field, we are pragmatic and innovative pioneers, providing energy-saving and innovative solutions for global industrial development, which is our ideal pursuit of hard work.

Focusing on the field of industrial temperature control, let China's energy-saving solutions nourish the world

For products, we are seekers of perfection and excellence

Follow Simpson for the latest news

If you have any needs or suggestions, please contact us

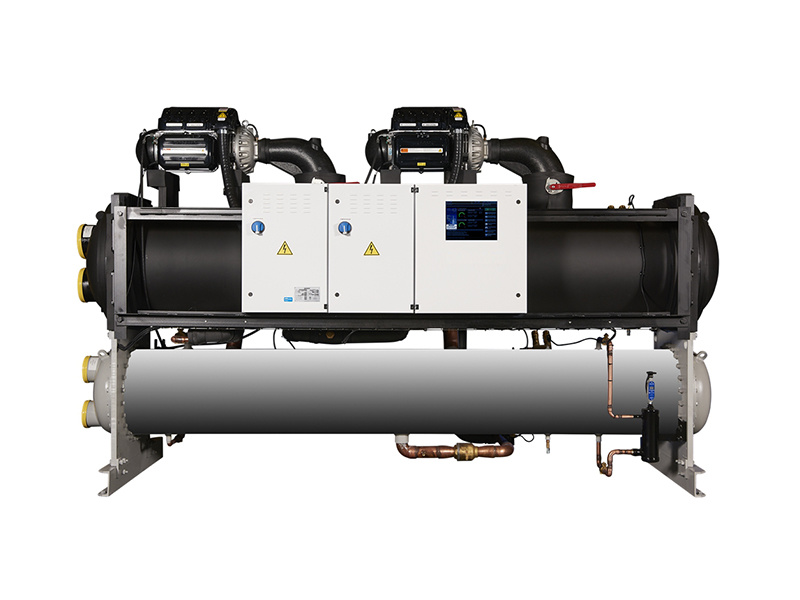

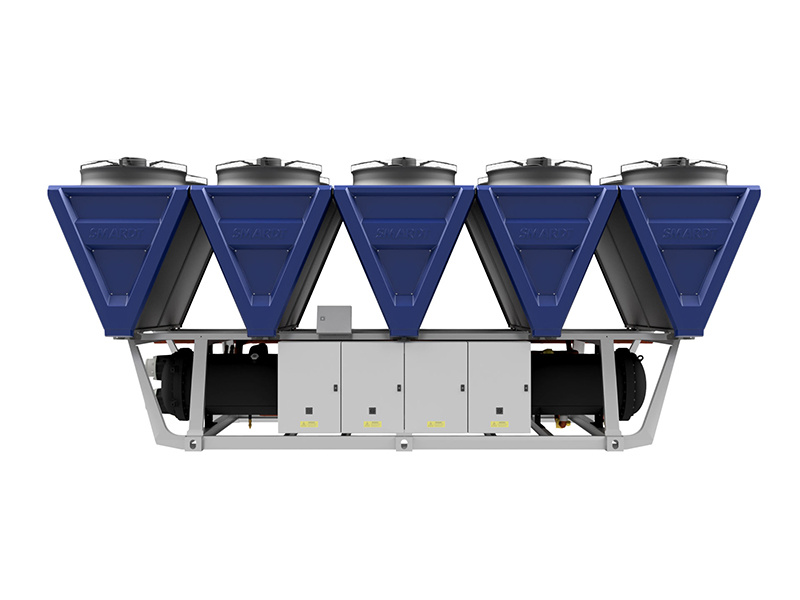

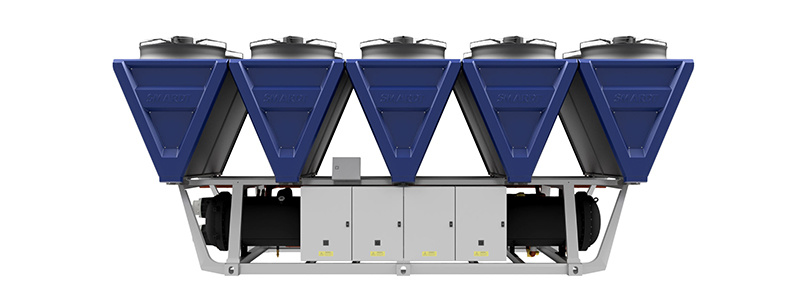

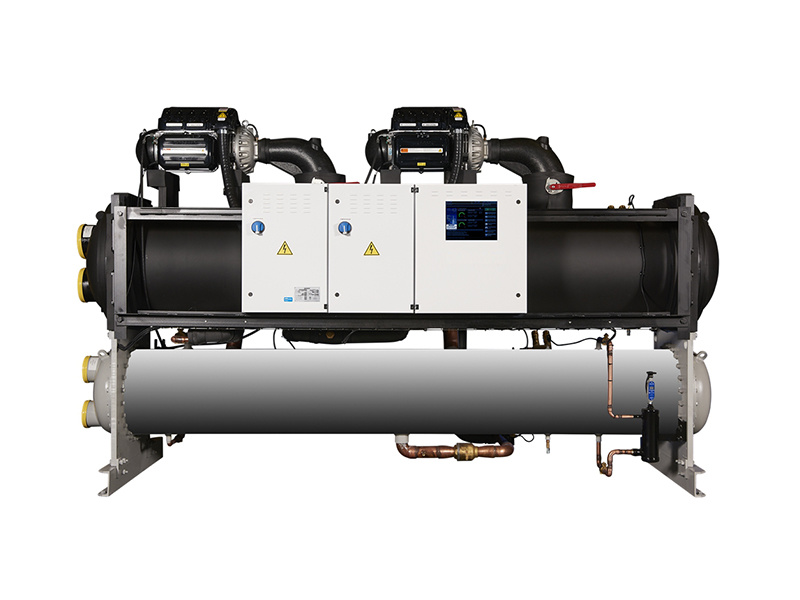

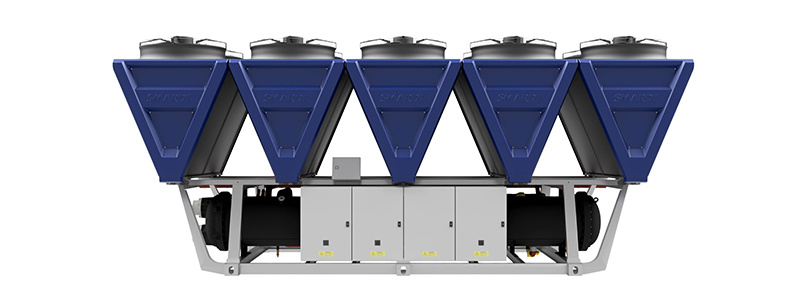

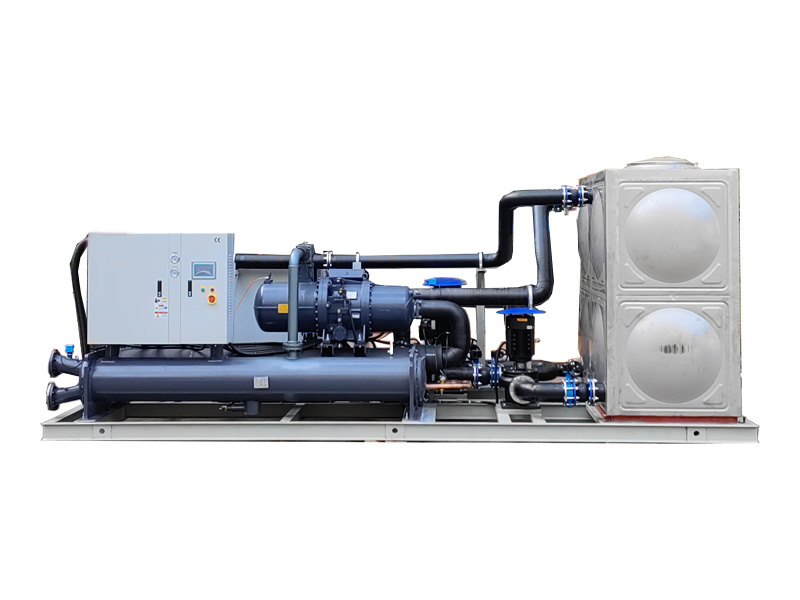

PRODUCTS

Medium temperature series

0℃~30℃Medium low temperature series

-5℃~ -35℃Low temperature series

-40℃~-60℃Ultra low temperature series

-50℃~-135℃Special Customized Series

-135℃ ~ 300℃ABOUT US

In the field of global industrial temperature control, we are pragmatic and innovative pioneers, providing energy-efficient and innovative solutions for global industrial development, which is our ideal pursuit.

Shenzhen Simpsan Refrigeration Technology Co., Ltd. is an international innovative enterprise focusing on industrial temperature control and refrigeration technology, integrating product research and development, production, sales and service. The company belongs to the Hong Kong Simpsan Group. Simpsan Group was established in Hong Kong in 1997 and established advanced chiller production lines, testing lines and standard enthalpy difference laboratories in Shenzhen. In 2021, a large-scale refrigeration unit production base was established in Wuhan, China. In China, Simpsan cooperates with Shanghai Jiaotong University, Tianjin University, Yangzhou University, Zhejiang University Refrigeration and Cryogenic Engineering Research Institute and other domestic HVAC and refrigeration technology research institutions, and has established R&D and after-sales institutions all over the country, and owns a number of patented technologies and completely independent intellectual property rights...

Simpsan Group Founded

Production Base (㎡)

After-sales Service Network

Patents and Certifications

Global Service Customers

Core Technology

Core Technology

500

+

Ten thousand yuan

R&D Investment

50

+

Authorized Patents

12.

5

%

R&D personnel ratio

Smart Manufacturing

Smart Manufacturing

+

Ten thousand yuan

R&D Investment

Shenzhen factory

Wuhan factory

NEWS

Understanding Air-Cooled Screw Chiller Heat Pumps: Efficiency and Applications

Air-cooled screw chiller heat pumps are an innovative solution in the realm of industrial cooling and heating. These systems are designed to transfer heat from one area to another, making them versatile for various applications in industrial settings. Unlike traditional systems that rely on water for cooling, air-cooled systems utilize ambient air, which can provide significant advantages in terms

2025-07-28

Air-Cooled Magnetic Levitation Chillers vs. Water-Cooled Chillers: Which Is Better?

Air-Cooled Magnetic Levitation Chillers vs. Water-Cooled Chillers: Which Is Better? The choice between air-cooled magnetic levitation chillers and water-cooled chillers can be daunting for businesses looking to optimize their cooling systems. With advances in technology and a growing emphasis on energy efficiency, understanding the strengths and weaknesses of each type is crucial. In this article,

2025-07-25

Debunking Myths: The Truth About Air-Cooled Magnetic Levitation Chillers

Debunking Myths: The Truth About Air-Cooled Magnetic Levitation Chillers Table of Contents 1. Introduction to Air-Cooled Magnetic Levitation Chillers 2. What Are Air-Cooled Magnetic Levitation Chillers? 3. Common Myths Surrounding Air-Cooled Magnetic Levitation Chillers 3.1 Myth 1: They Are Too Expensive to Operate 3.2 Myth 2: They Require Extensive Ma

2025-07-19

Understanding Variable Frequency Centrifugal Chillers: A Comprehensive Overview

Variable frequency centrifugal chillers are an advanced cooling solution widely utilized in various industrial applications. These chillers leverage the principles of variable frequency drive (VFD) technology to optimize the operation of the centrifugal compressor, allowing for precise control over cooling output. This adaptability makes them an excellent choice for facilities with fluctuating coo

2025-07-16

china variable frequency centrifugal chiller

The variable frequency centrifugal chiller represents a significant leap forward in cooling technology, offering unmatched energy efficiency for large-scale applications. This chiller operates by adjusting the compressor speed according to the specific cooling needs, making it a smart choice for energy-conscious businesses.

2025-07-16

Why Variable Frequency Centrifugal Chillers Are Essential for Modern Industry

Why Variable Frequency Centrifugal Chillers Are Essential for Modern Industry Table of Contents Introduction to Variable Frequency Centrifugal Chillers Understanding the Basics of Chiller Technology The Advantages of Variable Frequency Drives in Centrifugal Chillers Enhanced Energy Efficiency Improved Process Control and Stability

2025-07-13

Understanding Variable Frequency Centrifugal Chillers: Enhancing Efficiency in Industrial Cooling

Variable frequency centrifugal chillers are vital components in industrial cooling systems, designed to provide efficient temperature control in a variety of applications. Unlike traditional chillers that operate at a fixed speed, these advanced systems can adjust their motor speed based on cooling demand. This adaptability helps in optimizing energy consumption, often leading to significant cost

2025-07-10

How Water-Cooled Magnetic Levitation Chillers Enhance Industrial Efficiency

How Water-Cooled Magnetic Levitation Chillers Enhance Industrial Efficiency Table of Contents 1. Introduction to Water-Cooled Magnetic Levitation Chillers 2. Understanding the Technology Behind Magnetic Levitation 2.1 Principles of Magnetic Levitation 2.2 Components of Water-Cooled Chillers 3. Benefits of Using Water-Cooled Magnetic Levitation Chillers 3.1 Energy Efficiency and Cost Savings 3.2 Re

2025-07-07

The Future of Cooling: Exploring the Water-Cooled Magnetic Levitation Chiller

--- Water-cooled magnetic levitation chillers represent a cutting-edge advancement in cooling technology, combining efficiency and innovative design to meet the demanding needs of various industrial applications. These chillers utilize magnetic levitation (maglev) technology, which eliminates the need for mechanical bearings, resulting in reduced friction and wear over time. This not only enhances

2025-07-04

Revolutionizing Cooling: The Benefits of Water-Cooled Magnetic Levitation Chillers

Revolutionizing Cooling: The Benefits of Water-Cooled Magnetic Levitation Chillers Table of Contents Introduction to Water-Cooled Magnetic Levitation Chillers Understanding the Technology Behind Magnetic Levitation Chillers Energy Efficiency of Water-Cooled Magnetic Levitation Chillers Environmental Impact and Sustainability Reduction of Noise Pollution Low

2025-07-01

Maximizing Efficiency and Sustainability with Energy-Saving Chiller Units

As industries continue to evolve, the demand for efficient cooling systems has never been greater. Energy-saving chiller units have emerged as a game-changing solution, offering enhanced performance while significantly reducing energy consumption. These units are designed to provide effective cooling for various industrial applications, from manufacturing plants to large commercial buildings. One

2025-06-28

Unlocking Efficiency: The Benefits of Energy-Saving Chiller Units

Unlocking Efficiency: The Benefits of Energy-Saving Chiller Units Table of Contents 1. Introduction to Energy-Saving Chiller Units 2. What is an Energy-Saving Chiller Unit? 3. The Importance of Energy Efficiency in Industrial Cooling 4. Key Benefits of Energy-Saving Chiller Units 4.1 Cost Savings on Energy Bills 4.2 Reduced Environmental Impact 4.3 Improved Reliability and Lo

2025-06-25

Maximizing Efficiency: The Benefits of Energy-Saving Chiller Units

In today’s industrial landscape, energy efficiency is more than just a trend; it’s a necessity. Among the various industrial equipment available, energy-saving chiller units play a crucial role in optimizing performance and reducing energy consumption. These units are designed specifically to provide cooling solutions while minimizing the energy required to operate them, thereby contributing to lo

2025-06-22

china mobile container chiller unit

Introducing our Mobile Container Chiller Unit, the ultimate solution for portable cooling in any setting. This innovative unit combines mobility with high-performance cooling, making it suitable for industries like manufacturing, healthcare, and entertainment. The Mobile Container Chiller Unit is designed for easy relocation, providing instant cooling wherever it’s needed. Its plug-and-play functionality ensures minimal downtime, so you can focus on your work without interruptions.

2025-06-16

Understanding Industrial Temperature Control Equipment in Building and Decoration Materials

When it comes to managing environments in the building and decoration materials industry, industrial temperature control equipment plays a pivotal role. This equipment is designed to regulate temperature in various settings, ensuring that conditions are optimal for both human comfort and material integrity. As temperature fluctuations can significantly affect the performance and longevity of mater

2025-06-16

Unlocking Efficiency: The Crucial Role of Industrial Temperature Control Equipment in Construction

Unlocking Efficiency: The Crucial Role of Industrial Temperature Control Equipment in Construction Table of Contents 1. Introduction to Industrial Temperature Control in Construction 2. Importance of Temperature Control Equipment 3. Types of Industrial Temperature Control Equipment 4. Benefits of Using Temperature Control Systems 5. Applications in the Construction Industry 6. Enh

2025-06-13

Understanding Mobile Container Chiller Units: A Comprehensive Overview

Mobile container chiller units are specialized refrigeration systems designed for flexibility and efficiency in cooling applications. These units offer a unique solution for various industrial sectors, especially where traditional stationary chillers may not be practical. By providing portable cooling capabilities, they cater to businesses that require temperature-controlled environments for proce

2025-06-10

Unlocking Energy Efficiency: The Comprehensive Benefits of Variable Frequency Chillers

Unlocking Energy Efficiency: The Comprehensive Benefits of Variable Frequency Chillers Table of Contents 1. Introduction to Variable Frequency Chillers 2. Understanding Energy Efficiency in Cooling Systems 2.1 Definition of Energy Efficiency 2.2 Importance of Energy Efficiency 3. What are Variable Frequency Chillers? 4. Benefits of Variabl

2025-06-07

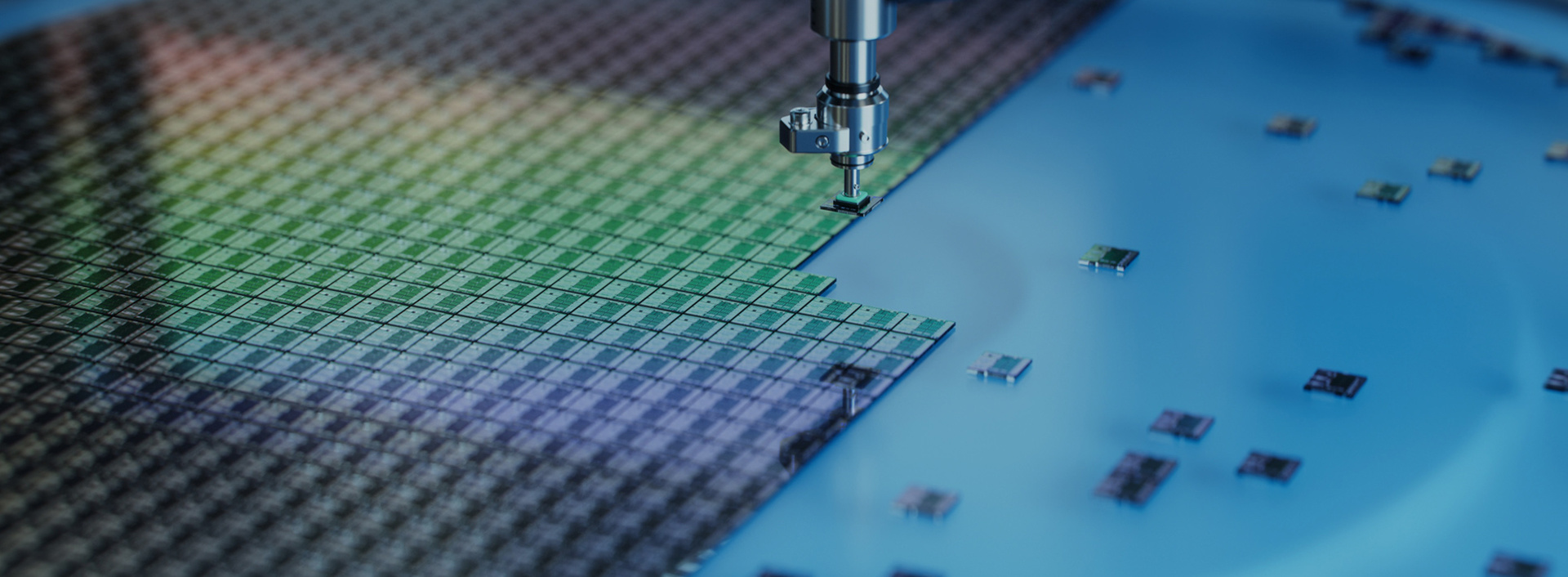

Understanding Cryogenic Chiller Systems: A Comprehensive Guide

Cryogenic chiller systems are specialized refrigeration units designed to achieve extremely low temperatures, typically below -150°C (-238°F). These systems are integral to various industrial applications, particularly in fields such as pharmaceuticals, semiconductor manufacturing, and scientific research, where precise temperature control is crucial for product integrity and process efficiency. T

2025-06-04

Understanding the Benefits of Low Temp Condensing Units in Industrial Refrigeration

Understanding the Benefits of Low Temp Condensing Units in Industrial Refrigeration Table of Contents 1. Introduction to Low Temp Condensing Units 2. What Are Low Temp Condensing Units? 3. Advantages of Low Temp Condensing Units in Industrial Refrigeration 3.1 Energy Efficiency and Cost Savings 3.2 Enhanced Performance in Industrial Settings

2025-06-01

Understanding Anti-Corrosion Chillers: Essential Insights for Industrial Cooling Solutions

In the industrial sector, maintaining optimal temperatures is crucial for preserving product quality and ensuring operational efficiency. One key component that plays a vital role in various cooling systems is the anti-corrosion chiller. These advanced chillers are designed to withstand harsh environments, preventing corrosion that can lead to equipment failure and costly downtime. Anti-corrosion

2025-05-29

What to Look for in a Glycol Chiller Supplier: Key Qualities for Optimal Performance

What to Look for in a Glycol Chiller Supplier: Key Qualities for Optimal Performance When it comes to selecting a glycol chiller supplier, the decision can significantly impact your operational efficiency and overall performance. Glycol chillers are vital for a variety of industrial applications, from food and beverage processing to chemical manufacturing. The right supplier not only provides high

2025-05-26

In industrial environments, especially those involving flammable substances, safety is of utmost importance. This is where explosion-proof chillers come into play. Designed specifically to operate in hazardous locations, explosion-proof chillers are engineered to prevent ignition of explosive gases or dust that may be present in the surroundings. These chillers are essential for maintaining the re

2025-05-23

Why Your Facility Needs an Explosion Proof Chiller for Safety

Why Your Facility Needs an Explosion Proof Chiller for Safety Understanding Explosion-Proof Chillers Explosion-proof chillers are specifically designed to operate safely in environments where flammable gases, vapors, or dust may be present. These chillers are built with robust materials and engineering standards that prevent ignition, ensuring that both personnel and equipment are protected fr

2025-05-20

quality magnetic levitation chiller

Experience next-generation cooling with the Magnetic Levitation Chiller, a state-of-the-art system engineered for maximum efficiency and precision. By leveraging magnetic levitation (maglev) compressor technology, this chiller delivers unparalleled energy savings and operational stability, outperforming conventional models with ease.

2025-05-19

Understanding Explosion-Proof Chiller Groups: Essential Insights for Industrial Applications

Explosion-proof chiller groups are specialized cooling systems designed to operate safely in hazardous environments where flammable gases, vapors, or dust may be present. These cooling systems play a critical role in various industries, including oil and gas, chemical processing, and pharmaceuticals. Understanding how these systems work and their benefits can help businesses make informed decision

2025-05-17

The Economic Advantages of Magnetic Levitation Chillers for Manufacturers

The Economic Advantages of Magnetic Levitation Chillers for Manufacturers Introduction In today's competitive manufacturing landscape, efficiency and cost-effectiveness are paramount. As manufacturers strive to optimize their operations, the choice of cooling systems has become a vital consideration. Magnetic levitation chillers, an innovative cooling solution, have emerged as a game-changer. This

2025-05-14

What kind of chiller should be matched with environmental testing equipment? Take a look.

In a certain environmental laboratory, a chiller is used to remotely cool and lower the temperature of laboratory equipment to maintain the normal operation of the test equipment. We know that environmental testing equipment mainly simulates the natural environment to test products, using artificially simulated environments in the short term to achieve the effect of products after 3-5 years.

2025-01-23

What should companies pay attention to when purchasing chillers? These 3 points are indispensable!

After years of development, the domestic chiller and freezer market has continued to grow, leading to the emergence of small and micro freezer factories. Due to their small scale and limited R&D and production capabilities, the overall quality of the units is relatively poor, and their performance and quality cannot meet the actual needs of enterprises. This is reflected in problems such as insufficient cooling capacity, frequent equipment malfunctions, high maintenance costs, and poor after-sales service.

2025-01-23

8 Common Causes and Solutions for Water Leaks in Chillers - A Must-Read!

The prerequisite for a chiller to function normally is that the water circulation, refrigerant circulation, and electrical control system must remain normal. If any aspect malfunctions, the chiller will not operate normally, affecting production. If a chiller leaks, it usually occurs in the water pipes and their connections. Addressing this promptly is beneficial for the normal operation of the chiller.

2025-01-23

Solutions for insufficient water flow fault codes in water dispensers - check here!

The chiller displays a "low water flow" error code and is shut down. This is generally caused by insufficient water flow, triggering the chiller's fault interlock and closing the water flow switch, causing the unit to stop.

2025-01-23

What causes the chiller to make noise? Ignoring the fifth reason will bring bad luck.

Sounds produced during chiller operation are unavoidable. For example, the rotation of fans and the friction between fan blades and air will generate noise. Normal sounds are acceptable, but serious, sudden, harsh, or irregular noises warrant attention! By listening, we can locate the approximate source of the noise and then take further action. Below are some common causes of noise and solutions. Let's take a look together with the Kaideli chiller editor!

2025-01-23

In your factory or laboratory, chillers are responsible for cooling and controlling the temperature of production equipment. They act like a dedicated caretaker, ensuring the equipment is kept at the optimal temperature. Therefore, you should treat them as carefully as you would your family to prolong their lifespan and maintain consistent, high-quality production.

2025-01-23

How to select a chiller? Master 6 aspects, even beginners can do it

Industry professionals frequently complain about the difficulty of choosing chillers. After comparing proposals from two or three chiller manufacturers, they often find the options to be very similar, yet the prices vary wildly! Choosing a chiller is like finding a suitable 'partner' for a company's production equipment; it requires not only compatibility but also a good match, so that the choice is the best and will last a long time.

2025-01-23

What is the purpose of checking the results of industrial chiller repairs? Find out now!

The purpose of checking the repair results of industrial chillers is to examine whether the chillers have recovered to their technical performance before the failure. By operating the units under different operating conditions, it is comprehensively assessed whether the repair has brought new problems to the chillers. Any problems found should be corrected immediately.

2025-01-23

How to lower the exhaust temperature of an industrial chiller? Just keep these points in mind

After prolonged operation, industrial chillers can easily experience excessively high discharge temperatures. This can lead to decreased performance and cooling efficiency of the industrial chiller.

2025-01-23

A brief analysis of the different cold water machine purchasing needs for different industries

Simpson Group is a large-scale refrigeration equipment manufacturing plant originating from advanced German refrigeration technology. We specialize in producing: chillers, industrial chillers, screw chillers, flooded chillers, low-temperature ice water machines, air-cooled and water-cooled chillers, explosion-proof chillers, customized chillers, semi-hermetic condensing units, screw condensing units, and other refrigeration equipment. We are a CCTV Brand Plan China Preferred Brand winner. Welcome to contact us for inquiries!

2025-01-23

Xinpusen

With energy-saving core, build environmental protection dream, help the global industrial new journey.

Providing energy-efficient and innovative solutions for global industrial development

If you are interested in our products, please leave your email address, and we will contact you as soon as possible, thank you!

Shenzhen Longhua District, Huan Guan South Road, Mayuan Industrial Zone, Xinpusen Industrial Park

0755-21017010

189-2749-0225

0755-23771793

Scan to add WeChat

© COPYRIGHT 2024 Shenzhen Simpsan Refrigeration Technology Co., Ltd. ALL RIGHTS RESERVED Powered by www.300.cn

CN

CN EN

EN